Assembly System Agreement between Corgentech Inc. and Mikron Corporation Denver

Contract Categories:

Business Operations

›

Supply Agreements

Summary

Corgentech Inc. and Mikron Corporation Denver entered into an agreement on May 23, 2006, for Mikron to sell and Corgentech to purchase a custom assembly system, as detailed in an attached quotation. The agreement outlines the sale terms, confidentiality obligations, intellectual property rights, and assignment restrictions. Corgentech retains ownership of any materials it provides, and both parties agree to keep shared information confidential. The agreement is legally binding and can only be changed in writing by both parties.

EX-10.52 3 v049021_ex10-52.htm

Exhibit 10.52

[ * ] = CERTAIN CONFIDENTIAL INFORMATION CONTAINED IN THIS DOCUMENT, MARKED BY BRACKETS, HAS BEEN OMITTED AND FILED SEPARATELY WITH THE SECURITIES AND EXCHANGE COMMISSION PURSUANT TO RULE 24B-2 OF THE SECURITIES EXCHANGE ACT OF 1934, AS AMENDED.

ASSEMBLY SYSTEM AGREEMENT

This Assembly System Agreement (the “Agreement”) is entered into on this 23 day of May, 2006, by and among Corgentech Inc. (“Corgentech,” also referred to in Exhibit A attached hereto as “customer” or “Purchaser”) and Mikron Corporation Denver (“Mikron,” also referred to in Exhibit A attached hereto as “Mikron,” “Mikron Corporation,” “Mikron Corporation Denver” or “Vendor”).

Recitals

Whereas, Corgentech and Mikron desire to enter into a legally binding contract for Mikron to sell, and Corgentech to purchase in exchange for the consideration set forth therein, the “Corgentech Assembly System” set forth on Quotation D05.05.012 attached hereto as Exhibit A (the “Quotation”), on the terms and conditions set forth in the Quotation.

Agreement

Now, Therefore, in consideration of the foregoing recitals and for other good and valuable consideration, the receipt and sufficiency of which are hereby acknowledged, Corgentech and Mikron hereby agree as follows:

1. Binding Effective Agreement. Mikron hereby agrees to sell, and Corgentech agrees to purchase in exchange for the consideration set forth therein, the Corgentech Assembly System set forth in the Quotation on the terms and conditions set forth in the Quotation. Notwithstanding anything in the Quotation that may be construed to contradict the following, including but not limited to Section 12.9 therein, by signing below, Corgentech and Mikron agree this Agreement shall be legally binding as of the date first set forth above.

2. Confidentiality. Notwithstanding anything in the Quotation that may be construed to contradict the following, Corgentech and Mikron hereby agree that the terms of the Confidential Disclosure Agreement among Corgentech, Mikron and The Tech Group dated March 2, 2006 shall govern the exchange of confidential information made pursuant to this Agreement.

3. IP and Materials Ownership. Any trial materials provided to Mikron by Corgentech shall remain the property of Corgentech. Nothing in the Quotation, including but not limited to Section 11.1.6 therein, shall be construed to provide Mikron with any right to use outside the specific scope of the Quotation, as modified by this Agreement, own, sell or reproduce any materials of Corgentech or any Proprietary Information or intellectual property of Corgentech provided under this Agreement or the Quotation.

4. Assignment. Mikron shall not assign its contractual rights or obligations under this Agreement or the Quotation to any third party without the prior written consent of Corgentech.

1.

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

5. Notices. All notices and other communications to Mikron from Corgentech shall be delivered to Mikron at the address set forth below:

Attention: Tom Graves

Mikron Corporation Denver

562 Sable Boulevard

Aurora, Colorado 80011

Fax ###-###-####

All notices and other communications to Corgentech from Mikron shall be delivered to Corgentech at the address set forth below:

Attention: Patrick Broderick

Corgentech Inc.

650 Gateway Boulevard

South San Francisco, CA 94080

Fax: 650 ###-###-####

6. Full Agreement; Modification; Waiver. This Agreement represents the full understanding between the parties of the subject matter contained herein. Neither this Agreement nor any term hereof may be changed, waived, discharged or terminated, but only by an instrument in writing signed by each of Corgentech and Mikron.

[Remainder of Page Intentionally Left Blank]

2.

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

In Witness Whereof, each of the parties hereto has caused this Agreement to be executed by its duly authorized officer as of the date first above written.

| Corgentech Inc. | |||

| /s/ John X. Regan | |||

| John X. Regan, | |||

| Vice President, Manufacturing |

Mikron Corporation Denver | ||

| | | |

| By: | /s/ Clark Neft | |

| Clark Neft, | ||

| President | ||

[SIGNATURE PAGE TO THE CORGENTECH ASSEMBLY SYSTEM AGREEMENT]

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

3 of 62

Exhibit A

Quotation D05.05.012

Corgentech Assembly System

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

4 of 62

January 27, 2006

The Tech Group

Attn: Mark McElfresh

14677 North 74th St.

Scottsdale, AZ ###-###-####

| RE: | Quotation D04.05.012 | |

| Corgentech Assembly System |

Dear Mr. McElfresh:

We offer the following assembly concept, based on our discussions and review of your project requirements.

Mikron is an industry leader in high speed, precision assembly machines. Our equipment, in use throughout the world, produces over 40,000,000 parts each day for automotive, medical and consumer product manufacturers. We are committed to solving your production problems through design, production and timely delivery of reliable automation equipment at a competitive price.

Our proposed concept utilizes our GO5™ cam-driven, linear indexing assembly system. These systems allow for a high degree of scalability and flexibility allowing for a straightforward connection to downstream components.

We hope the enclosed proposal meets your requirements and gives you the confidence to work as a partner with Mikron Corporation Denver. We thank you for the interest you have shown in our products and look forward to hearing from you.

Sincerely,

| Tom Graves | Jim Mueller |

| Regional Sales Manager | Application Engineer |

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

5 of 62

| 1. | Proposed solution |

| 1.1 | Task definition |

Automatic assembly system for your Corgentech Assembly:

Please note that the machine is capable of producing more than 18,300,000 good parts per year with one machine operator and 1 part’s tender. Net output is calculated based on 3,600 parts per hour in 6,000 hours per year and approximately 78% line efficiency.

G05™ Solution

Our solution is based on our G05™ assembly cells with the following advantages:

| o | A parts transfer system with free pallets provides flexibility, speed and accuracy; |

| o | Various pallet sizes to accommodate your products; |

| o | Tested reliable and highly standardized basic cell; |

| o | Easily accessible compact linear configuration; |

| o | G05™ cam or numeric controlled (NC) movement in the same cell; |

| o | Systematic operation control check after every operation; |

| o | User friendly operator interface; |

| o | Efficient use of working space; |

| o | Option for integrating slow operations in a fast throughput system; |

| o | Progressive investment option; |

| o | Option for connecting to other production systems. |

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

6 of 62

| 2. | Key points |

| 2.1 | Production |

Approximately 47 “good” parts per minute

Without considering stoppages due to production control

| 2.2 | Price |

| System | Approx. $ [*] |

| Bagging System (cost plus 10% integration margin) | Approx. $ [*] |

| Level 3 FDA Validation Support | Approx. $ [*] |

| 2.3 | Shipping time |

Approximately thirty four (34) weeks from receipt of signed purchase order, completion of the Kickoff Meeting and receipt of agreed-to specifications, drawings and component parts, and the resolution of all technical and commercial issues.

| 2.4 | Warranty |

12 months or 3500 hours whichever comes first.

Parts and labor

| 2.5 | Confidentiality |

Customer confidentiality is an integral part of our corporate culture. Your competitive edge is also ours. All files are anonymously managed to guarantee optimum discretion.

| 2.6 | Floor space requirements |

Approximately: 49 x 21 feet. Our modular designed assembly systems can be configured to meet your space requirements.

| 2.7 | Training |

Mikron Corporation provides comprehensive training for the operation and maintenance of the mechanical, electrical, pneumatic and software systems.

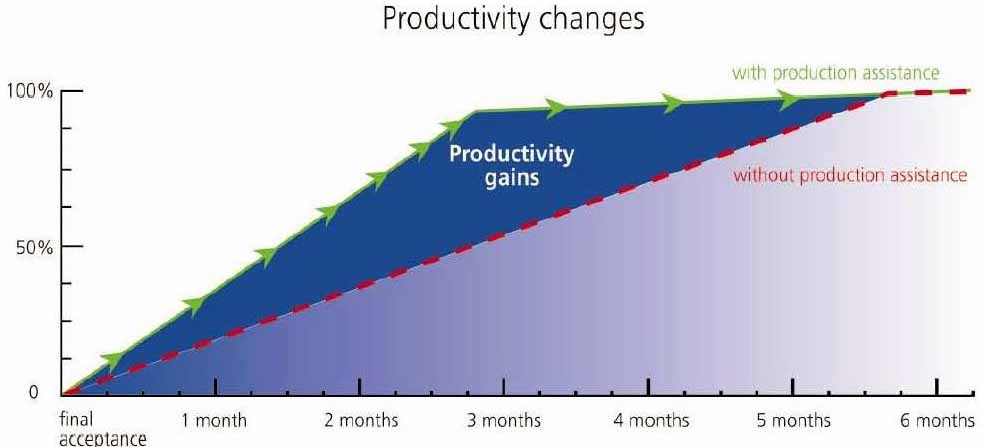

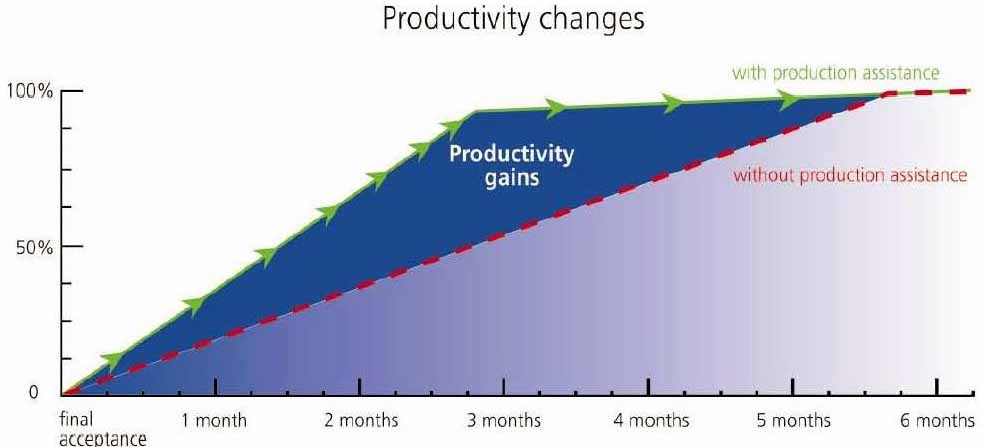

| 2.8 | Production assistance: improved productivity |

Production assistance can be offered as an option.

| 2.9 | Customer service |

After office hours, on Saturdays and Sundays, and during public holidays, a special phone number is reserved for our customers who need to reach us.

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

7 of 62

Machine remote connection by modem enables fast diagnosis of your control system.

| 2.10 | Project management |

Our project teams maintain regular contact with you throughout the life of the project.

The following diagram shows how a standard project develops. Very close cooperation throughout the project provides optimum time and cost control.

[*]

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

8 of 62

| 3. | Rights to proposal |

As part of this proposal, Mikron Corporation Denver has divulged and delivered to the Customer certain proprietary information which includes, but is not limited to, technical requirements, specifications, print, data and other information relating to the description and operation of the system which is the subject of this proposal, its components, equipment, options and related services, designs, processes, techniques, documentation, pricing, installation and safety. The Customer acknowledges that certain information is secret and the sole and exclusive property developed or owned by Mikron Corporation Denver. The Customer further agrees that during the term of the consideration of this proposal and at all times subsequent (subject to contract provisions which may modify this agreement), Customer shall not disclose or deliver such proprietary information to any person or entity, other than an employee of Customer, nor shall Customer reverse engineer such information; it being acknowledged that it is private, confidential and a trade secret under the sole ownership and development of Mikron Corporation Denver. In the event of the breach of these covenants by the Customer, Mikron Corporation Denver shall have all rights in law or in equity to enforce this covenant including, without limitation, the right to an award for damages and reasonable costs and attorneys’ fees incurred by Mikron Corporation Denver in the enforcement of these covenants. The providing of such information by Mikron Corporation Denver to the Customer shall not be construed by either party to be a publication of such proprietary information.

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

9 of 62

| 4. | Parts to be assembled |

| 4.1 | Description of parts to be assembled |

| No. | Description | Sample | Drawing No. | Rev. | Date |

| 01 | Corgentech Assembly | YES | Not Provided |

| 4.2 | Description and drawings of components (products) to be assembled |

[*]

| 4.3 | Definition of variants |

This proposal considers no variants.

| 4.4 | Overall Assumptions |

Certain points require clarification and may have an influence on the technical and commercial aspects of the quotation. This proposal is based on the following assumptions.

NOTE: If the assumptions stated within this proposal prove not to be true, project schedule and/or costs to The Tech Group could change.

4.4.1 [*]

4.4.2 [*]

4.4.3 [*]

4.4.4 [*]

4.4.5 [*]

4.4.6 [*]

4.4.7 [*]

4.4.8 [*]

4.4.9 [*]

4.4.10 [*]

4.4.11 [*]

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

10 of 62

| 5. | Description of the assembly system |

The proposed concept is based on the use of free pallets to transport the parts to be assembled. The parts are supported, during successive operations, on specific fixtures known as “nests”, which form an integral part of the pallets.

The proposed G05™ concept is based on linear assembly cells with indexed pallets. It may consist of one or more G05™ units, depending on the number of operations.

Pallets entering the G05™ are mechanically indexed and placed in front of each workstation. Pallets are transported from cell to cell then recycled with a belt conveyor.

| Pallet dimensions: | 120 x 120 mm |

| Number of pallets: | 125 pallets |

| Number of nests: | 3 nests (2-Up) |

| Pallet coding system: | Balluff |

Please refer to the “Description of standard basic machines” section in this proposal for more information on standard assembly cells.

| 5.1 | Sequence of operations and description |

The sequence of operations described below is based on a review of the submitted parts and your Request For Quote. This concept combines our extensive assembly experience with the product knowledge that you provided. Any requested changes to this proposal will be thoroughly reviewed by our engineers.

Cell 1: 2-Module G05™ 120

[*]

Cell 2: 2-Module G05™ 120

[*]

CELL 3: 1-Module G05™ 120

[*]

CELL 4: 1-Module G05™ 120

[*]

| 5.2 | Machine speed |

[*]

| 5.3 | Effective output |

[*]

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

11 of 62

| 5.4 | Feeding systems |

Specific feed systems are provided to feed each part assembled. The type of feeding system depends on each part’s physical characteristics:

[*]

Important: If changes are made on the basis of non-conforming prototype parts, Mikron Corporation Denver shall not be liable for changes or modifications necessary to ensure feeding systems operate correctly.

| 5.5 | Noise level |

Maximum of 80dBA, measured three feet from the loudest source, four feet from the floor in the Mikron Corporation Denver Facility.

| 5.6 | Floor space required |

See Section 2.6, herein.

| 5.7 | Calibration |

Neither calibration devices nor calibration programs are included as part of the basic machine.

| 5.8 | Machine capability index |

If required, an optional statistical analysis of machine performance can be conducted. The Customer shall submit the acceptance requirements to Mikron Corporation Denver for assessment. Then, Mikron Corporation Denver and the Customer shall determine the tolerances and Cm and CmK values.

The machine capability analysis shall be conducted by the Customer with the measuring tools supplied by Mikron Corporation Denver (except for specific tools to be specified after the order) and in Mikron Corporation Denver’s facility. This study shall be carried out after preliminary acceptance and shall be part of this acceptance.

Mikron Corporation Denver is not involved in the process capability analysis.

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

12 of 62

| 6. | Installation Conditions & Terms |

| 6.1 | Packing |

The cost of packing is included in the price. The equipment is FOB Aurora, Colorado.

| 6.2 | Installation supervision and final acceptance |

Installation supervision with 2 Mikron Corporation Denver personnel for twenty-one (21) days and the final acceptance are included in the price.

| 6.3 | Unspecified work outside Mikron Corporation Denver Facility |

Certain work relating to the machine can be invoiced in accordance with the following conditions:

6.3.1 Connection to services

The work and cost of electrical, compressed air and possible water connections are not included in the price and shall be invoiced at the hourly rates shown herein.

6.3.2 Production assistance

Production assistance is not included in the price and shall be invoiced at the hourly rates shown herein.

6.3.3 Other work executed outside Mikron Corporation Denver’s Facility

Other work executed outside Mikron Corporation Denver’s facility shall be invoiced at the hourly rates shown herein.

6.3.4 Labor rates

| Mechanical Technicians: traveling and working time Electronic and Software Engineers: traveling and working time | $[*]/hour $[*]/hour |

Invoices are prepared in accordance with the time sheets and expense reports prepared by Mikron Corporation Denver staff.

Please refer to the General Terms and Conditions Of Sale section of this proposal for more information.

6.3.5 Remote maintenance

Setting up the system

Price per hour on line (Including telephone costs) $[*]/hour

| 6.4 | Validity of proposal |

90 days.

After finalization of all technical and commercial issues

Please refer to the Terms and Conditions Of Sale section of this proposal.

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

13 of 62

| 6.5 | Payment terms |

Initial payment is due upon receipt of invoice. All other payments are due net 10 days from receipt of invoice.

[*]% of Total Contract Price with Purchase Order

[*]% of Total Contract Price at Preliminary Design Review

[*]% of Total Contract Price at Final Design Review

[*]% of Total Contract Price at Acceptance Test at Mikron

[*]% of Total Contract Price at Acceptance Test at The Tech Group

Subject to Credit Department approval, terms are net 10 days from receipt of invoice. Accounts past due are assessed a service charge of 1.5% per month. If accounts or service charges thereon are not paid when due, or suit is brought, additional reasonable costs of collecting, including attorneys’ fees, will be charged.

| 6.6 | Acceptance terms |

Pre-acceptance shall take place in our facility in the presence of one or more representatives of your company. Costs of customer’s travel and accommodations are not included in the bid price.

Final acceptance shall take place in your facility after installation and startup.

The terms of pre-acceptance and final acceptance shall be specified and mutually agreed upon before the contract is concluded. Six (6) hours of production time is provided in our proposal.

Utilities must be ready and stable prior to the start of the final acceptance run. Components to specification and in required quantities must be available prior to the start of pre and final acceptance runs.

Acceptance takes place in the presence of both parties and is considered successful if the machine assembles the number of good parts shown herein.

A certificate of acceptance shall be drawn up for each acceptance. These certificates shall be signed by both parties.

Note: The customer shall not, without the prior written approval of Mikron Corporation Denver, use the equipment for production purposes before the final acceptance has taken place and the final acceptance report has been signed by the customer.

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

14 of 62

| 7. | Risk Management |

| 7.1 | Efficiency |

[*]

| 7.2 | Machine downtime |

Machine downtime is directly linked to execution of the assembly machine cycle and is the responsibility of Mikron Corporation Denver. This downtime is classified in three categories:

Feed systems blockage: Most of these stoppages are generated by feed systems that have relatively low inherent efficiency because of the feeder design and part characteristics.

Gray area - non conforming parts, assembled and then detected as non-conforming: It is not always possible to determine whether the part was already non-conforming during feed system filling or if the part had been damaged by the machine and thus detected as non-conforming. This gray area is accepted as Mikron Corporation Denver’s responsibility.

Reject parts caused by the system: This concerns parts damaged by the assembly system.

7.2.1 Unplanned production stoppage

These stoppages are random interruptions due to the two factors shown below and are the Customer’s responsibility.

Non conforming parts: These are parts damaged during manufacture or shipment, for example, bent parts, molding defects, parts not de-burred, etc.

Staff, operators: These are short unplanned absences, interruptions due to insufficient staff or operator ability.

7.2.2 Planned production stoppage

These stoppages are interruptions with a fixed frequency as described below and are the responsibility of the Customer.

Pauses: Meals and intermediate break periods.

Shift Changeover: Often synchronized with break periods.

Clean room procedures: Mainly cleaning equipment and safety procedures during batch changeover.

Re-certification: Recalibration or re-certification procedures according to a fixed schedule, determined by the Customer, can significantly affect output.

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

15 of 62

Series or batch changeover: This procedure can result in a 1 to 20% variation in output, depending on the frequency of changeover and the method of changeover.

Periodic preventive maintenance: Preventive maintenance work executed in accordance with predetermined schedules.

7.2.3 Definition of effective output - machine efficiency

Good parts are counted after a batch of parts has been produced in a given amount of time.

Bad or incomplete parts attributable to the Customer are added and the result becomes the corrected number of good parts.

Production stoppage times attributable to the Customer are deducted from the production time and the result becomes the corrected production time.

The actual system output will be defined by dividing the corrected number of good parts by the corrected production time. The result shall, as a minimum, be equivalent to the actual output shown herein.

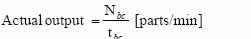

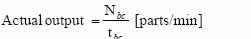

Nbc = Corrected number of good parts

Nb = Number of good parts

Nic = Number of incomplete parts attributable to the Customer

Tbc = corrected production time

Tb = total production time

Tic = stoppage time attributable to the Customer

Tc = cycle time

The efficiency of the Mikron system is calculated as follows:

7.2.4 Quality and cleanliness of parts

Actual output will depend on the quality of the components to be assembled. They shall be clean, de-burred, degreased, undamaged, non magnetic and manufactured within the tolerances shown on the drawings.

Components submitted in bulk shall not contain foreign debris.

The output shown is based on present information. It will only be possible to confirm the actual output after testing samples.

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

16 of 62

| 7.3 | Information on production costs |

The following data is based on the mean values. It may vary, depending on the equipment provided with the standard cells.

7.3.1 Energy costs

Cell energy consumption:

The values given in the following table are indicative only. Actual values depend on specific units and equipment integrated on the units.

| Cell | Electric energy (3x480V ±10%) | Compressed air (80 psi) | Connection value (electrical protection) |

| G05™ 120 | Approx. 4 kVA | Approx. 131 cu. ft./hr | 25 A |

7.3.2 Maintenance costs

The Mikron machine design minimizes mechanical stresses, reducing parts wear and downtime due to maintenance.

Machine maintenance costs depend on how well the Customer adheres to the recommended preventive maintenance schedule. The frequency of maintenance work will depend on actual production rates.

Periodic maintenance tables, listed in the technical documents, provide information on the type, frequency and duration of preventive maintenance work.

7.3.3 Spare parts costs

Average spare parts costs are divided into 2 different categories:

| • | Parts recommended for making up the basic stock when the machine is purchased. This stock is made up jointly with our services, according to your needs. |

| • | Parts used for routine machine operation (per year). |

[*]

| 7.4 | Customer responsibilities |

7.4.1 Machine operation

Operating and maintaining the machine requires certain skills on the part of the customer’s staff to which these tasks will be entrusted. Operating the machine correctly depends partially on the operator’s capabilities.

The proposed machines are designed for ease of operation.

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

17 of 62

Operation of the machine should not require any special operator skill levels other than understanding the relationships between machine functions and commands (Human Machine Interface).

Maintenance should be provided by technically trained staff that understand basic mechanical, information technology and electrical concepts.

The additional information required for production, upkeep and maintenance of the machine is provided during training (refer to the “Customer Service” section of this proposal for more information on training details).

7.4.2 Information to be provided to Mikron Corporation Denver

At the time the order is placed, Mikron Corporation Denver requires the following information and documents:

| • | Final drawings of all parts to be assembled, including variants, and the CAD files, in DWG or DXF format |

| • | Component matrices per variant |

| • | Final specifications for the assembly process |

7.4.3 Equipment supplied by the Customer

When required, special equipment supplied by the Customer may be integrated into the machine. The following responsibilities then are incumbent on the Customer:

| • | Delivery of the equipment to Mikron Corporation Denver on the agreed schedule; |

| • | Provide separate assessment and acceptance of the supplied equipment; |

| • | Ensure the equipment output does not affect the overall system output; |

| • | Manage and assume responsibility of the interface between the supplied equipment and the Mikron machine; |

| • | Provide startup and set process parameters according to product requirements. |

Delivery and shipment of this equipment to Mikron Corporation Denver is the responsibility of the Customer.

| 7.5 | Project schedule |

The project schedule must be followed to ensure on time delivery. The final project schedule is fixed at the point the purchase order is signed.

| 8. | Changes and deviations from Mikron Corporation Denver standards |

| 8.1 | Changes during the project |

Changes requested by the customer during the project shall be examined for their feasibility. Mikron Corporation Denver shall be notified in writing of any change involving parts to be assembled, accompanied by an amended drawing clearly showing the extent of the changes made.

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

18 of 62

Mikron Corporation Denver engineers will evaluate the impact on the machine. As a result, Mikron Corporation Denver reserves the right to change its price and schedule.

| 8.2 | Deviation from Mikron Corporation Denver standards |

This proposal was prepared on the basis of our standard machines. Any departure from these standards requires an investigation to determine the feasibility and cost.

| 9. | Parts for testing and preliminary acceptance |

Parts for testing feed systems, machine setting and preliminary acceptance will be delivered and reshipped, without cost to Mikron Corporation Denver, in accordance with the schedule below.

Each delivery shall be accompanied by a packing list and parts quality protocol.

Non-compliance with delivery times or part quality could have an effect on the shipping date and machine costs.

| Delivery schedule of parts for testing | |||

| Project Schedule [wks] | Parts* time [wks] | Project stages | Quantities of parts (for each part type) |

| 34 | 2 | Customer order | 2 - 3 parts |

| 34 | 6 | Construction start | 3000 parts |

| 34 | 17 | Acceptance of systems | For 1 hour of production or a minimum of one times feed system capacity |

| 34 | 22 | Machine start up | G05™: For 50 hours of production, or according to Mikron Corporation Denver specifications |

| 34 | 27 | Internal acceptance | For 6 hours of production or according to Mikron Corporation Denver specifications |

| 34 | 30 | Preliminary acceptance of machine | For 12 hours of production or according to Mikron Corporation Denver specifications |

| *Parts delivery times, in numbers of weeks after the order | |||

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

19 of 62

A final schedule for receipt of parts will be prepared and submitted in a timely manner after the order.

The minimum quality of delivered parts (capability index) shall be the same or superior as is required for assembled parts, for projects with statistical analysis protocols.

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

20 of 62

| 10. | Warranty |

Our warranty is in accordance with our Terms and Conditions of Sale and forms an integral part of this proposal.

Should you need any further information, please do not hesitate to contact us.

We recommend a meeting to discuss your project thoroughly at your facility in the near future. We will present this proposal formally to you and your people to fully describe how each step of this process is designed to meet and exceed your requirements.

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

21 of 62

| 11. | Terms and Conditions of Sale |

| 11.1 | General Terms and Conditions of Sale |

| 11.1.1 | The following terms and conditions of supply and payment shall be deemed to have been accepted by the customer when he places the order. General conditions of business of the customer and departures from the present conditions shall be valid only if they are expressly acknowledged in writing by Mikron Corporation. |

| 11.1.2 | Save where otherwise agreed, the “Conditions for the machinery acceptance procedure” of Mikron Corporation and the “Installation Conditions” applicable to assembly work, including Mikron Corporation’s current assembly charge rates, shall be deemed to have been agreed. |

| 11.1.3 | All agreements and declarations of the contracting parties having legal effect shall be valid only if they are made in writing. |

| 11.1.4 | The customer shall not transfer his contractual rights to third parties without the express consent of Mikron Corporation. |

| 11.1.5 | Delivery periods recited herein shall commence upon finalization of all technical and commercial details (as hereinafter explained) or the receipt of the required down payment, whichever occurs later. “Finalization of all technical and commercial details” shall include Vendor’s receipt of complete specifications, samples and trial materials from Purchaser. Delivery periods are dependent upon the availability of raw materials and components from Vendor’s suppliers as prevailing on the date of quotation, and Vendor therefore reserves the right to modify the delivery periods due to changes in such conditions. Shipment will be made in the name of the Purchaser and will be at the risk of the Purchaser from the time that the merchandise leaves the Vendor’s manufacturing facility. Purchaser shall promptly inspect all shipments and shall notify Vendor of all defects, shortages or deficiencies within forty-eight (48) hours of Purchaser’s receipt of the shipment. Vendor shall not be liable for any losses or damages to any merchandise damaged in transit from and after the time such merchandise has left Vendor’s manufacturing facility. Purchaser agrees to look solely to the carrier and Insurer with respect to any and all losses or damages to shipments, and agrees not to make any claim against the Vendor for same. |

| 11.1.6 | Purchaser shall supply to Vendor at Purchaser’s expense such quantities of trial materials as are specified in this quotation or are reasonably required by Vendor together with such written specifications as may be necessary to finalize all technical and commercial details. Such trial materials shall be delivered at Purchaser’s expense including shipping costs, to the Vendor’s manufacturing facility in the United States, as specified in this quotation, on or before the date(s) specified in this quotation or otherwise reasonably required by Vendor. Unless otherwise specified in this quotation, such trial materials shall become the property of Vendor and shall not be returned to Purchaser. |

| 11.1.7 | Prices set forth in this quotation for parts, tools and machines built at Vendor’s facilities in the United States of America are fixed in United States Dollars and shall not be adjusted. The purchase price shall be paid in compliance with the agreed payment terms. The payment dates shall be respected, even if minor parts of the deliveries and performance are lacking, or if subsequent work has proved necessary but does not prevent the delivered goods from being used. All payments for delivered merchandise which are not received within thirty (30) days after their respective due dates shall bear interest from their respective due dates until paid in full, at the rate of one and one-half percent (1.5%) per month, or the maximum interest rate permitted by applicable law, whichever shall be less. |

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

22 of 62

| 11.2 | Verification, Preliminary and Final Acceptance and Clearance of the Delivered Goods for Production Purposes |

| 11.2.1 | Save where otherwise agreed, preliminary acceptance shall take place on the premises of Mikron Corporation Denver, by agreement with the customer, within ten (10) days of notification of readiness for dispatch being given by Mikron Corporation Denver. Final acceptance shall take place on the customer’s premises. Preliminary and final acceptance shall be effected in accordance with “conditions for the machinery acceptance procedure” and shall end with the compilation of a preliminary or final acceptance report. |

| 11.2.2 | The customer shall not withhold acceptance and signing of the preliminary or final acceptance report by reason of minor defects, in particular those which do not significantly impair the functional quality of the delivered goods and services. Mikron Corporation Denver shall make such shortcomings good within a reasonable period. Defects which could not be recognized at the time of preliminary or final acceptance shall be notified by the customer to Mikron Corporation Denver in writing as soon as they are detected, failing which the items concerned shall be deemed to have been accepted. Mikron Corporation Denver shall not be liable for defects that are notified after expiration of the warranty period. |

| 11.2.3 | If final acceptance does not take place at the latest within three (3) months of delivery of the machinery for reasons which are not attributable to Mikron Corporation Denver, said machinery shall be deemed to have been definitively accepted by the customer. |

| 11.2.4 | Should defects occur, the customer shall in all cases allow Mikron Corporation Denver to verify the goods supplied and the repairs made thereto pursuant to Section 11.3 of these conditions. |

| 11.2.5 | The customer undertakes not to use the machinery for production purposes without the written approval of Mikron Corporation Denver before the final acceptance report has been signed or before definitive final acceptance has taken place. |

| 11.3 | Warranty and Liability for Defects |

| 11.3.1 | Notwithstanding the provisions herein, the warranty period shall be twelve (12) months or 3,500 operating hours. It shall begin to run on the date of final acceptance, or at the latest, three (3) months after delivery by Mikron Corporation Denver. For deliveries of goods and services which are not brought into service on the operating site by Mikron Corporation Denver, or by technicians specifically authorized by Mikron Corporation Denver, or which have been used for productive purposes before definitive final acceptance without the consent of Mikron Corporation Denver, the latter shall give no warranty. The warranty period on repaired or replaced components begins to run for a further period of six (6) months from the date of replacement, completion of repairs and acceptance or at the latest until the end of the warranty period for deliveries and services. |

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

23 of 62

| 11.3.2 | The warranty shall expire immediately if the customer or third parties operate the delivered goods inexpertly, undertake inexpert modifications or repairs, fail to use original Mikron Corporation Denver replacement parts during the warranty period or do not give Mikron Corporation Denver an opportunity to remedy the defect itself. In addition, the customer shall make sure that the damage is not allowed to become more extensive. |

| 11.3.3 | Mikron Corporation Denver undertakes, at the written request of the customer, to repair or replace as quickly as possible, at its own discretion, and in its own works, all parts of the Mikron Corporation Denver deliveries which demonstrably become defective or unusable due to poor material or inadequate workmanship before the expiration of the warranty period. Replaced components shall become the property of Mikron Corporation Denver. |

| 11.3.4 | Special suitability for an intended use or the assurance of a particular performance capability exists only where such an assurance has been given contractually in express and direct terms. Such an assurance presupposes use of the delivered goods and services for their intended purpose and in compliance with all the contractually agreed functional parameters. On the completion of final acceptance of the delivered goods and services, evidence of suitability for the intended purpose, or assurance of a particular performance capability of the goods and services, shall be deemed to have been definitively provided or given. If the assured properties are not satisfied, or only satisfied in part, on final acceptance of the goods and services, the customer shall solely be entitled to repairs by Mikron Corporation Denver within a reasonable period. For this purpose, the customer shall grant Mikron Corporation Denver the necessary time and opportunity. Should this repair prove impossible in full or in part, the customer shall only be entitled to a suitable price reduction. |

| 11.3.5 | The warranty and liability do not extend to damage which has demonstrably been caused by poor materials, defective design or inadequate workmanship, e.g. as a result of natural wear and tear, defective maintenance, failure to comply with operating or safety instructions, excessive strain, unsuitable working materials, chemical or electrolytic influences, building or assembly work which was not performed by Mikron Corporation Denver or its subcontractors and for any other reasons not attributable to Mikron Corporation Denver itself. |

| 11.3.6 | In the case of goods and services provided by sub-contractors who were prescribed by the customer, Mikron Corporation Denver shall only give a warranty within the framework of the warranty obligations of such subcontractors. |

| 11.3.7 | In respect of material defects, poor design or workmanship and failure to comply with assured characteristics, the customer shall have no rights in claims apart from those expressly stated herein and in no case amounting to more than the value of the defective parts of the delivery. |

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

24 of 62

| 11.3.8 | Liability for consequential damages resulting from defects and damages to property of all kinds, e.g., loss of production, loss of use, loss of orders, loss of profit, failure to perform or effective breach of contract, or claims for compensation made by way of redress - together with all other direct and indirect damage -is hereby expressly excluded. This exclusion of liability shall not apply to willful intent or gross negligence on the part of Mikron Corporation Denver, but it shall apply to willful intent or gross negligence on the part of servants. |

| 11.3.9 | Mikron Corporation Denver shall only be liable for claims by the customer in cases of willful intent or gross negligence. |

| 11.4 | Title |

| 11.4.1 | Title to all machines shall vest in Purchaser upon (a) completion of installation at Purchaser facility and (b) the payment in full of the purchase price. Title to all parts, tools and other items shall vest in Purchaser upon delivery and payment therefore. |

| 11.4.2 | Grant of Security Interest |

1. Customer and Mikron agree that title to the Equipment provided herein does not pass until Customer has paid for the Equipment in full. Notwithstanding the foregoing, and not in limitation of the foregoing, Customer hereby grants to Mikron a security interest in and to the Equipment, and any and all additions, accessions and substitutions thereto or therefore (hereinafter called the “Collateral”) to secure Customer’s payment for the Equipment, and any and all other existing or future obligations of Customer to Mikron (the “Obligations”). Customer agrees to execute such documentation as may be required by Mikron to further evidence and perfect such security interest, including without limitation financing statements.

2. Except for the security interest granted herein, Customer is, or to the extent that this Agreement states that the Collateral is to be acquired after the date hereof, will be, the owner of the Collateral free from any adverse lien, security interest or encumbrances, and that Customer will defend the Collateral against all claims and demands of all persons at anytime claiming the same or any interest therein. The Collateral will be kept at Customer’s address stated in this Agreement.

3. Until default Customer may have possession of the Collateral and use it in any lawful matter, and upon default Mikron shall have the immediate right to the possession of the Collateral. Upon such default and at any time thereafter, or if it deems itself insecure, Mikron may declare all Obligations secured hereby immediately due and payable and shall have the remedies of a secured party under Article 9 of the Colorado Uniform Commercial Code. Mikron may require Customer to assemble the Collateral and deliver or make it available to Mikron at a place to be designated by Mikron which is reasonably convenient to both parties. Expenses of retaking, holding, preparing for sale, selling or the like shall include Mikron’s reasonable attorney’s fees and legal expenses.

11.4.3 Intellectual Property

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

25 of 62

The Equipment provided herein contains and requires intellectual property (including the intellectual property of third parties) in order to operate, such as software, formulas, processes and know how (the “Intellectual Property”). By selling Customer the Equipment, Mikron is not transferring legal or equitable title to the Intellectual Property. However, Mikron hereby grants to Customer a non-exclusive, perpetual worldwide, royalty-free license to use the Intellectual Property so long as and only in connection with Customer’s use of the Equipment and only if Customer is not in default in its Obligations to Mikron (the “Mikron License”). The Mikron License is strictly limited to use with the Equipment and may not be utilized independently of the Equipment. The Mikron License may not be transferred, assigned or pledged without the written consent of Mikron. Any transfers in violation of the foregoing shall be voided and without effect.

| 11.5 | Protected Rights |

| 11.5.1 | In the case of standard Mikron Corporation chassis and components forming part of Mikron Corporation’s scope of supply, Mikron Corporation shall be responsible for assuring that the acquisition or use of the delivered object, or parts thereof, does not infringe the patent rights of third parties in the customer’s own country. Mikron Corporation Denver shall be entitled to contest or otherwise settle purported claims of third parties in or out of court in any appropriate manner. The customer shall grant due authority to Mikron Corporation Denver for that purpose. In the case of equipment components specific to the customer and for the deliveries and services as a whole, Mikron Corporation Denver declines all liability, as it is impossible for Mikron Corporation Denver to make sure that the patent rights of third parties are not affected or infringed. |

| 11.5.2 | The customer gives a full guarantee that the manufacturer of objects according to his specifications does not infringe the protected property rights of third parties; he undertakes to release Mikron Corporation Denver from any resulting claims on grounds of infringement and claims for compensation. |

| 11.5.3 | Each contracting party reserves all rights in calculations, drawings and technical documents made available by him to the other party. The receiving contracting party acknowledges these rights and will treat the relevant documents as his own business secrets and refrain from using them otherwise than for their intended purpose for which they were made available. |

The customer shall be entitled to use the software, drawings, know-how and documentation himself to the stipulated extent, but shall not make them available to third parties or make copies. Any extension or modification of the software or its use otherwise than for the intended purpose by the customer shall require the prior written consent of Mikron Corporation Denver.

| 11.6 | Environmental and operational safety |

| 11.6.1 | The customer undertakes to comply with the operating instructions and safety rules handed over with the delivered goods, and to instruct his own personnel accordingly, so as to permanently guarantee the safe and environmentally compatible operation of the delivered goods. |

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

26 of 62

| 11.6.2 | Existing safety instructions and danger notices on the machinery must not be removed. Instructions that are poorly secured or have been damaged must be repaired or replaced immediately. Mikron Corporation Denver undertakes to replace unusable safety instructions for the customer at any time and to make the requisite number of copies available. Improvements to the safety instructions shall be accepted and respected by the customer at all times at the request of Mikron Corporation Denver. |

| 11.6.3 | Technical modifications to machinery, in particular if they are liable to endanger safety of operating personnel or of the environment, shall only be made with the written consent of Mikron Corporation. If that consent is withheld, they shall be removed immediately. |

| 11.6.4 | The customer shall inform Mikron Corporation Denver without delay if an accident involving the delivered goods has occurred, or if it transpires that operation of the delivered goods presents a risk. |

If the customer fails to comply with any of these requirements for the preservation of environmental and operational safety, he shall release Mikron Corporation Denver from all the resulting obligations to provide compensation to third parties.

| 11.7 | Prior Agreements |

Purchaser expressly acknowledges that these terms and conditions shall supersede all prior agreements, discussions or correspondence between Purchaser and Vendor (including the respective employees, agents or representatives of either), written or oral, and that Purchaser is not relying upon any oral or written representation of Vendor other than those expressly contained herein.

| 11.8 | Force Majeure |

In the event of any Act of God, war, fire, explosion, accident, flood or riot, sabotage, lack of adequate fuel, power, raw materials, labor, containers or transportation facilities, or compliance with governmental requests, laws, regulations, orders or actions of unforeseen technical difficulties, breakage or failure of machinery or apparatus; or national defense requirements, or any other event, whether or not of the class or kind enumerated herein, beyond the reasonable control of Vendor, or labor trouble, strike, lockout or injunction (provided that Vendor shall not be required to settle a labor dispute against its own business judgment), which makes impossible or impractical the manufacture or transportation of subject goods or acquisition of a material upon which the manufacture of the subject goods is dependent, i.e., any “Force Majeure,” Vendor at its option may either terminate the contract or extend the delivery period, without liability to Purchaser, except that in the event of cancellation, Vendor shall return any portion of the purchase price which remains unexpended as of the date of Vendor’s election to terminate.

| 11.9 | Applicable Law |

The parties agree that any contract between the parties which may arise from this quotation shall be deemed entered into at Aurora, Colorado, USA, and shall be interpreted and construed in accordance with the laws of Colorado. Both parties hereby consent to the jurisdiction of the courts of the State of Colorado and more specifically the judicial district within which Vendor maintains an office or manufacturing facility, but their consent shall not limit jurisdiction with regard to this matter to that district within the State.

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

27 of 62

| 11.10 | Taxes |

Purchaser shall be responsible for all taxes (other than income taxes) due and payable in connection with the delivery of, and transfer of title to, the merchandise that is the subject of this agreement.

| 11.11 | Modification |

This agreement shall not be changed or modified except by written instrument signed by both parties.

| 11.12 | Rights or Remedies |

Any forbearance by Vendor in the exercise of Vendor’s rights or remedies in response to any breach by Purchaser shall not be construed to be a waiver of, nor shall it preclude, the exercise of any right or remedy.

| 11.13 | Cancellation |

Except as expressly stated to the contrary herein, the Purchaser may not cancel this agreement.

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

28 of 62

| 12. | Mikron Assistance Beyond Installation |

| 12.1 | Assistance rates |

Based on your request, we can provide support personnel at your facility for the purpose of start-up, demonstration, overhaul and repairs.

Our conditions for this work are:

| Travel time | $[*]/hr. |

| Standard working time | $[*]/hr. |

| Overtime | 50% extra |

| Travel expenses | (See paragraph 12.6 below) |

| Charges for lodging and meals | To be determined |

| Compensation for extras | To be determined |

The above charges are valid for normal conditions. Should any unforeseen extra charges be incurred or, if the support personnel are able to prove that they are unable to meet expenditure with the allowances granted, a proportionate adjustment shall be effected subsequently.

Cost increase adjustment reserved.

| 12.2 | Travel time |

Travel time includes all project-related travel, including travel to and from the project site and daily travel.

| 12.3 | Working time |

| 12.3.1 | The standard workweek is 40 hours. If standard working hours are decreased for reasons beyond our control, then standard working hours must be paid in accordance with the terms of our agreement. |

| 12.3.1 | Hours worked over and above the normal work shift will apply as overtime. |

| 12.4 | Waiting time |

If, for reasons beyond our control, the support personnel are prevented from working or from leaving when the work is completed, the time lost shall count as waiting time and be charged as standard working time. The same applies to hours lost on account of local public holidays.

| 12.5 | Holidays |

Holidays and the corresponding wage and traveling rates shall be subject to a separate agreement.

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

29 of 62

| 12.6 | Traveling expenses |

| | Traveling expenses shall include return fare and transportation cost at the place of installation, as well as insurance, freight and duty for baggage and tools, the cost for procuring the identity papers, vaccination and other measures required in the country of installation. |

| 12.7 | Incidental expenses |

Incidental expenses shall include charges for meals, tips, laundry and miscellaneous expenses.

| 12.7.1 | Illness and accidents |

| 12.7.1.1 | Our support personnel are insured against illness and accidents. |

| 12.7.1.2 | In case of illness or accident (also non-factory accidents) Mikron Corporation Denver will be responsible for wages as well as for expenses in connection with medical treatment. |

| 12.7.1.3 | Customers are expected to undertake the requisite precautionary measures against accidents in their facility. |

| 12.8 | Taxes |

Any taxation which may arise in connection with the dispatch of our support personnel will be chargeable to the customer.

| 12.9 | Formation of contract |

The contract shall be deemed to have been concluded when the customer accepts the completed order.

| 12.10 | Regulations in force at destination |

The customer must inform Mikron Corporation Denver of any regulations and all laws, governmental or others, in force, which affect the execution of the installation, operation of the machinery/equipment as well as to the well-being of Mikron Corporation Denver personnel.

| 12.11 | Preliminary work |

Mikron Corporation Denver supplies dimensional drawings as part of the project. The customer must prepare the workspace with all necessary utility connections prior to the arrival of support personnel. This should include parts, equipment, and any necessary materials. The customer shall make arrangements in good time and at his own expense for the issue of any residence or work permits which may be required for our personnel and shall also pay any fees or premiums for additional insurance coverage required by regulations in force.

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

30 of 62

| 12.12 | Tools, auxiliary equipment and materials |

Mikron Corporation Denver shall provide our support personnel with the hand tools necessary for the job. They should be maintained in a secured location. Insurance against theft, fire and water damage is left to the customer. On completion of the job, the tools and other items that we have supplied must be returned to Mikron Corporation Denver.

Upon request, the customer shall supply any additional labor, material, and tools necessary.

The customer assumes full responsibility for accidents, their consequences and any material damage that can be traced to the auxiliary equipment. If any special factory Installation Conditions Quotation D04.05.012 47 of 90 considerations have to be taken into account, then the customer shall expressly bring those to the attention of our support personnel.

| 12.13 | Duration of support |

| 12.13.1 | A target date for completion of work shall only be binding when accepted in writing by Mikron Corporation Denver. Work begins when Mikron Corporation Denver receives instructions from the customer to send our support personnel to their facility. |

| 12.13.2 | The completion date shall be extended if 1) the customer fails to supply instructions required for the work, 2) the customer makes changes which delay the work, 3) any other conditions beyond our control make it impossible to meet the original date, or 4) the purchaser is behind schedule with the work required to fulfill contractual obligations or fails to provide the required skilled labor. |

12.13.3 The imposition of a penalty for delay in the completion of work requires written agreement.

12.13.4 The purchaser is not entitled to claim indemnity or cancel the contract if the work is delayed.

| 12.14 | Testing and acceptance of machinery/equipment |

| 12.14.1 | The machinery/equipment is ready for acceptance when it is placed into production. Acceptance can occur even if nonessential parts are missing or readjustments are necessary or if the machinery/equipment cannot be taken into service for reasons beyond our control. |

| 12.14.2 | As soon as the purchaser is notified that the machinery/equipment is ready for acceptance, it shall be inspected in the presence of the person in charge of the work. Any deficiencies must be reported immediately to Mikron Corporation in writing. If the customer fails to comply, the machinery/equipment shall be deemed accepted. |

| 12.14.3 | If the tests prove that the machinery/equipment does not fulfill the terms of the contract, the customer shall give Mikron Corporation Denver an immediate opportunity to correct any deficiencies. |

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

31 of 62

12.14.4 The purchaser shall not be entitled to claim indemnity or cancel the contract on account of unsatisfactory work.

| 12.15 | Work not covered by the contract |

The customer shall not request support personnel to perform any work that is not covered by the contract without express agreement from Mikron Corporation.

| 12.16 | Guarantee |

12.16.1 Mikron Corporation Denver guarantees any material we supply and install.

12.16.2 The customer shall not be entitled to claim indemnity or cancel the contract on account of poor workmanship.

| 12.17 | Liability |

Mikron Corporation Denver shall carry out the work in accordance with the terms of the contract and shall fulfill our guarantee.

| 12.18 | Validity |

| 12.18.1 | These general conditions apply to all work and services carried out by us or on our behalf in regards to support, commissioning or repair of machinery/equipment. The conditions shall be binding if applicable at the conclusion of the contract unless Mikron Corporation Denver agrees in writing to other conditions. |

| 12.18.2 | Any responsibility accepted by the support personnel on behalf of the customer or a third party shall only be binding if they are covered by the scope of the contract or are acknowledged by Mikron Corporation Denver in writing. |

| 12.19 | Additional conditions |

| 12.19.1 | If the customer requests support at a fixed price, those terms must be agreed to in writing. The Terms and Conditions of Sale shall also apply in such cases, unless other conditions are agreed to. |

| 12.19.2 | The fixed price shall only cover work and services specified in the contract. It is based on the following provisions: 1) all preliminary work to be carried out by the customer shall be completed in a timely manner, 2) the support work can proceed without hindrance due to matters beyond our control. |

| 12.19.3 | If a fixed price is agreed upon for the support work, then this shall be based on the standard working time specified herein. If our support personnel have to observe shorter working hours, then the resultant longer working period costs, including daily expenses, will be charged to the customer. The customer shall be responsible if support personnel are prevented from executing their work thorough causes for which Mikron Corporation Denver is not responsible. |

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

32 of 62

| 12.20 | Terms of payment |

| 12.20.1 | Payments to the agreed terms shall be sent to Mikron Corporation Denver at our billing address without any deductions for cash discount, expenses, taxes or dues of any kind. |

| 12.20.2 | Payment shall be deemed effected when the particular sum is available to us. The purchaser shall not withhold or reduce payment on account of complaints or claims or of counterclaims we did not agree to. Payment shall also be made if the support work is delayed or prevented by reasons beyond our control. |

| 12.20.3 | If the purchaser defaults on payment, he shall be liable for interest from the date on which the payment was due, without further warning, at a rate depending on the terms prevailing at the purchaser’s registered address, but not less than 6 percent per year. Payment of default interest shall not release the purchaser from paying the sum due under the terms of the contract. |

| 12.21 | Place of jurisdiction and law applicable |

These conditions are to be governed by, and interpreted in accordance with, the laws of the United States. Denver, Colorado is hereby designated as the seat of jurisdiction for both parties.

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

33 of 62

| 13. | Project development description |

Mikron Corporation Denver is organized on a project team basis. Key personnel, such as the Project Manager, are assigned for the duration of the project and others are assigned as specialized resources are required throughout the various stages of the project. The Project Manager has complete responsibility for the management and direction of all phases of the project, including design, fabrication, assembly, test and supervision of both installation and start-up. The Project Manager’s authority provides you with a single point of contact for all communications with Mikron Corporation for the resolution of project issues.

The Mikron Corporation Denver project team consists of the Project Manager, production engineers, quality engineers, automation technicians and mechanics who participate in the project when their special skills are required. At each important milestone throughout the project, a progress report is provided by our project team.

[*]

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

34 of 62

| 13.1 | Kick-off Meeting |

Mikron project team introduction

Following award of the contract, Mikron Corporation personnel will attend a Kick-off Meeting at Customer’s facility. The purpose of this meeting is to introduce the key individuals of the Mikron Corporation team to the key individuals of the Customer’s team. In addition, the proposal is reviewed to discuss all pertinent aspects and to obtain common direction for project requirements. Following completion of this meeting, a detailed schedule of activities is finalized and issued.

| 13.2 | Project reviews |

Monitoring important project stages

The Mikron Corporation project team provides a progress report at each important stage of the project.

| 13.3 | Preliminary Design Review |

After the Project Kick-off Meeting, the members of the Mikron Corporation design team are assembled and the concepts of the proposed system are reviewed. These concepts are defined in the form of preliminary design drawings so that each member is aware of his or her individual responsibilities for overall project completion.

The preliminary designs are reviewed with Customer, at Mikron Corporation’s facility to assure a complete understanding of the course of action to be taken with the project.

| 13.4 | Final Design Review |

The Final Design Review is conducted at the Mikron Corporation facility in Aurora, Colorado. A complete mechanical assembly drawing package is reviewed for approval of the overall design. The electrical and controls engineers also review the drawings of panels, schematics and the overall structure of the software. Following this review, the details of the system are released for fabrication and assembly.

Mikron Corporation Denver openly invites Customer to participate in all aspects of the engineering phase. Frequent visits and meetings to review concepts and progress enhance the overall design effort.

| 13.5 | Certification tests |

Testing and operating approval

When the final stage for tuning a machine is reached, a series of internal tests are carried out to verify compliance with specification requirements. These tests are based on documents jointly prepared with the customer:

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

35 of 62

| • | Mechanical and software function tests; |

| • | Production throughput checks; |

| • | Checks on assembly performance. |

These tests help prepare for the pre-acceptance stage.

| 13.6 | Pre-acceptance |

Operating and production test before shipping

The performance of the Assembly Line is demonstrated thoroughly at Mikron Corporation Denver prior to shipment. The line is run for a 6-hour period (or other period agreed between Customer and Mikron Corporation) to demonstrate that it can produce the required output. Parts that do not meet the drawing requirements for tolerances are not counted against the actual number of acceptable assemblies during the acceptance testing. Any slow-down due to lack of operator performance is not counted when determining the line rate.

It is the responsibility of the Customer to supply a sufficient quantity of parts and inert material for the testing and acceptance tests of the Assembly Line. A quantity of components will be agreed to following defined criteria of testing the machine at the Kick-off Meeting.

Component parts not received in the quantities or by the schedule specified may result in additional test and debug by Mikron Corporation Denver at the Customer’s facility prior to Final Acceptance Test. This additional cost is not included in the system price and will be invoiced at the time and material rates specified herein.

| 13.7 | Final acceptance |

Operating and production test after installation

The performance of the Assembly System is demonstrated thoroughly at the Customer’s facilities prior to final acceptance. The line is run for a 6-hour period (or other period agreed between Customer and Mikron Corporation) to demonstrate that it can produce the required number of assemblies at the required output. Parts that do not meet the drawing requirements for tolerances are not counted against the actual number of acceptable assemblies during the acceptance testing. Any slowdown due to operator performance is not counted when determining the line rate.

Note: After final acceptance, production assistance can be provided by a Mikron Corporation team to assist with your production start-up (please refer to the “Customer Service” section in this proposal for more information on this service).

| 13.8 | Debriefing |

Project review after production start-up

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

36 of 62

Approximately three (3) months after the Final Acceptance of the system, the Mikron Corporation project team conducts a final project review to verify the system performance. The project is then handed over to our After-Sales Services, which provides support thereafter.

| 14. | Customer parts control |

At various stages of the project, the Customer is required to provide production parts and inert material for testing, station set-up and system run-off. The parts should be delivered to Mikron Corporation in accordance with the “Parts Delivery Schedule” of this proposal.

| 14.1 | Parts tracking |

Mikron Corporation will receive, classify, inventory and store all Customer parts. In every step of the process, we comply with all confidentiality agreements.

| 14.2 | Parts use and stock control |

Stored parts are used for testing and checks on the production line. The next batches are delivered in accordance with the plan provided and they follow the same process, according to project requirements.

| 14.3 | Parts disposal |

When the project is completed, Mikron Corporation returns or directly disposes of any leftover parts. Disposal will comply with environmental standards and regulations. Costs for either option are charged to the Customer and are not included in the proposal.

| 14.4 | Confidentiality |

Industry products and technologies often require a high degree of confidentiality.

The following policies are in place to ensure the confidentiality of all projects.

14.4.1 General policy

We define, with our Customer, the degree of confidentiality consistent with the project. The confidentiality guidelines must be clearly delineated so that no breaches of confidentiality negatively impact the Customer.

Mikron Corporation ensures that the confidentiality requirements regarding protecting Customer parts and restricting access of unauthorized people to the Customer’s project are met.

Each project is internally coded to eliminate any direct reference to the product and the Customer’s name.

Strict adherence to this policy ensures the Customer’s confidentiality and our reputation in the industry.

[ * ] = Certain confidential information contained in this document, marked by brackets, has been omitted and filed separately with the Securities and Exchange Commission pursuant to Rule 24b-2 of the Securities Exchange Act of 1934, as amended.

37 of 62

| 15. | Training |

| 15.1 | Basic training |

Training in the use and maintenance of the machine is provided in our facility in accordance with our standard program.

| 15.2 | Target audience |

Appropriate training for the Customer’s staff will be provided as follows:

| • | Staff without special qualification levels, who have a basic understanding of the machine’s operator interface, can take operator training. |

| • | Staff with technical training should take upkeep and maintenance training in order to understand the required mechanical, information technology and electric fundamentals. |

| 15.3 | Development and contents |

Planned duration: Approximately 3 days

First day

| • | Introduction to the Mikron group and company visit. |

| • | Main mechanical elements. |

Second day

| • | Controls and electrical elements. |

| • | Level 1 automation includes all necessary automation training to effectively run and maintain the machine. |

| • | Specific elements and feeding systems. |

Third day

| • | Specific elements and feeding systems. |

| • | After-sales service, spare parts list and preventive maintenance. |

| 15.4 | Additional training |

Mikron Corporation Denver provides additional training at an optional price. This optional training consists of 2 modules, “Level 2 automation” and “Level 3 automation” of 1 ½ days each.

Target audience

The following training modules are intended for people trained in software programming.