Distribution Agreement between Raven Industries, Inc. and AgEagle Aerial Systems, Inc. (February 17, 2016)

Contract Categories:

Business Operations

›

Distribution Agreements

Summary

This agreement, effective February 17, 2016, is between Raven Industries, Inc. and AgEagle Aerial Systems, Inc. AgEagle appoints Raven as the exclusive worldwide distributor of its fixed wing precision agricultural unmanned aerial systems for use in agriculture. AgEagle must terminate all other distribution agreements and ensure existing distributors either become Raven dealers or cease sales. Raven will market and sell the AgEagle System as its exclusive product in this category. The agreement also gives Raven first rights to distribute future AgEagle products, subject to negotiation.

EX-10.1 4 ex10_1.htm EXHIBIT 10.1 ex10_2.htm

Exhibit 10.1

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

DISTRIBUTION AGREEMENT

This Distribution Agreement (this “Agreement”), is entered into effective as of February 17, 2016 (the “Effective Date”), between Raven Industries, Inc., a South Dakota Corporation with its principal place of business located at 205 E. 6th Street, Sioux Falls, SD 57104 (“Raven”), and AgEagle Aerial Systems, Inc., a company duly incorporated under the laws of Nevada, with offices at 117 S. 4th Street, Neodesha, KS 66757 (“AgEagle”). Raven and AgEagle are hereafter individually referred to as the “Party” and jointly as the “Parties.”

WHEREAS, Raven is engaged in research, design, development, engineering, manufacturing, integration, sales and support of technology and products for precision agriculture; and

WHEREAS, AgEagle is engaged in research, design, development, engineering, manufacturing, integration, sales and support of systems and products for aerial collection of data for precision agriculture, including, but not limited to the AgEagle System and any Future AgEagle System, only to the extent it is applicable to this Agreement by the terms contained herein, (collectively “Products”) ; and

WHEREAS, the Parties wish to grow their existing markets and to expand into new and emerging markets that build on their core competencies; and

WHEREAS, the Federal Aviation Administration (“FAA”) is expected to finalize rules for commercial use of unmanned aerial systems by June 2016; and

WHEREAS, the Parties desire to set forth an exclusive relationship for the sale, marketing and distribution of AgEagle’s fixed wing precision agricultural unmanned aerial system (the “AgEagle System”), on the terms and conditions set forth in this Agreement.

NOW, THEREFORE, in consideration of the foregoing and other good and valuable consideration, the receipt and sufficiency of which is hereby acknowledged, the parties hereto agree as follows:

| 1. | Distribution Grant; Exclusivity. |

1.1 Exclusive Appointment. Subject to the terms of this Agreement, AgEagle hereby appoints Raven as its sole and exclusive distributor worldwide (the “Territory”), of the AgEagle System during the Term of this Agreement in the field of agriculture, including but not limited to turf maintenance, spot specific crop and land management, horticulture, botany and the science, research and development of seeds, soil, fertilizer and other agricultural products (the “Field”). In furtherance thereof, except as set forth in this Agreement, AgEagle will not sell, directly or indirectly, the AgEagle System to any person or entity and shall refer any inquiries it receives for the AgEagle System for use in the Territory in the Field to Raven. Raven will purchase the Products from AgEagle and resell them in Raven’s own name and for its own account. AgEagle acknowledges and agrees that Raven shall have the right, but not the obligation, to establish one or more dealers, sub-distributors or other third party sellers of the AgEagle System in the Territory for use in the Field.

1.2 Exclusive Worldwide Distributor. As a condition precedent to this Agreement, AgEagle MUST, as of the Effective Date of this Agreement, no longer sell and/or supply the Products to any dealer, distributor, Original Equipment Manufacturer (“OEM”), or any other entity, of any type, other than Raven. All dealers and/or distributors of AgEagle prior to and up to this Agreement, MUST either cease to be dealers/distributors of AgEagle, or agree to be dealers/distributors of Raven. Specifically, it is a condition precedent to the duties and obligation owed by Raven under this Agreement and the Stock Purchase Agreement, entered into by and between the Parties, on or about February 2016 (the “Stock Purchase Agreement”) that the subsequent conditions are met:

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

| 1.2.1. | Prior to, or within ten (10) days of the execution of this Agreement, AgEagle must provide written proof that it has fully terminated exclusivity, and/or any other written or oral distribution or dealer agreements with any of its existing, or future contemplated, dealers and/or distributors, including, but not limited to any and all dealers and/or distributors in Australia and Canada, who previously had exclusive agreements. This proof shall also include notification that in order for the Australian and Canadian dealers to remain dealers of the Products they must become dealers of Raven. Proof of termination, as provided herein, must be provided in a verifiable writing, within the time period noted above. |

| 1.2.2. | That AgEagle’s existing distributors, including those in Australia and Canada, agree to become dealers of Raven, or otherwise cease sales of the AgEagle System; and |

| 1.2.3. | That during the Term of this Agreement, Raven shall be the ONLY distributor of the AgEagle Systems in the Territory, pursuant to the restriction provided herein. |

If the foregoing terms are not satisfied, this Agreement and the Stock Purchase Agreement, are null and void and Raven shall owe no duties or obligations under this Agreement or the Stock Purchase Agreement, and AgEagle shall retain no rights thereunder. Additionally, if the conditions precedent are not met, AgEagle must pay back any and all sums paid to it either in advance or during the Term of the Stock Purchase Agreement or this Agreement.

1.3 AgEagle System Exclusivity. Raven agrees that during the Term of this Agreement, it will market and sell the AgEagle System as Raven’s exclusive product offering for fixed wing agricultural unmanned aerial vehicles, subject to the terms and conditions provided herein.

1.4 Future AgEagle Systems. AgEagle may design and manufacture multicopter, rotor wing and unmanned aerial spraying systems (“Future AgEagle System”) subsequent to the Effective Date. AgEagle must notify Raven of any development of Future AgEagle Systems. Raven agrees that once notified by AgEagle of the development of any Future AgEagle System, Raven will first seek to purchase such Future AgEagle System from AgEagle before purchasing a directly competitive system from any third party, provided, however, that the purchase price for the Future AgEagle System is competitive. The decision and timing to purchase any such Future AgEagle System shall be determined by Raven, in its sole and absolute discretion.

| 1.5 | First Right of Refusal. |

| 1.5.1. | Future Product Distribution Rights. AgEagle agrees that Raven shall have the first right of refusal to be the exclusive or non-exclusive distributor in the Territory of any Future AgEagle System in the Field. If AgEagle desires to appoint a dealer, distributor or any third party to sell any or all of the Future AgEagle System or other Products, either current or future, AgEagle shall notify Raven and Raven shall have the right, but not the obligation, to be the exclusive distributor or a non-exclusive distributor in the Territory of the Future AgEagle System in the Field. If Raven desires to be the exclusive distributor of any such Future AgEagle System or other AgEagle Product, the Parties shall negotiate in good faith the terms of such distribution agreements, including any minimum quantities, territories and other provisions. Any agreement for Raven to be a distributor of any Future AgEagle System of other AgEagle Products will be set forth in a new agreement or an amendment to this Agreement, executed by the authorized representatives of the Parties. |

2

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

| | 1.5.2. | Controlled Technology Release. The Parties will use reasonable efforts so that the AgEagle System components, features and additional add-ons thereto (the “System Products”) introduced after the execution of this Agreement and which are intended to become, or become System Products sold to Raven, under this Agreement, may be introduced by Raven as System Products private-labeled under the Raven brand prior to such System Products being introduced by AgEagle or any other distributor of AgEagle, and the terms of such introduction shall be mutually agreed upon by the Parties. |

1.6 AgEagle Distribution Rights. The parties further agree that nothing contained in this Agreement shall limit the right of AgEagle to sell, and to appoint dealers, distributors and other third party sellers to sell (a) the AgEagle System and/or System Products for uses in fields other than the Field, as defined herein, and (b) Future AgEagle Systems and other products manufactured by AgEagle, only to the extent the Parties have agreed that Raven is not an exclusive distributor for the Future AgEagle System and/or other Products, current or future.

2. Testing/demonstration Systems. AgEagle will supply Raven with eight (8) AgEagle Systems for demonstration, marketing, testing, product validation, and any other purposes Raven determines, on or before March 1, 2016, at no current or future cost to Raven. One (1) or two (2) of the eight (8) AgEagle Systems provided hereunder shall be delivered to Raven as soon as reasonably practicable following the execution of this Agreement. Raven shall retain permanent ownership rights to the eight (8) AgEagle systems. Raven will validate these eight (8) systems through use of standards and parameters to be agreed upon by both Parties in writing prior to delivery (“Standards”). If AgEagle’s System does not meet the applicable Standards, Raven shall give AgEagle notice of failure to meet such Standards, and AgEagle shall have ten (10) business days to either cure all deficiencies identified, or propose a plan, which must be agreed to by the Parties in writing, to cure all deficiencies identified, if such deficiencies cannot be cured within ten (10) business days. Raven shall have the right to reasonably accept or reject the proposed plan. Notwithstanding the foregoing, if AgEagle’s failure to meet the Standards, delays the distribution of the AgEagle Systems, in any way, then Minimum Sales Amounts and/or Purchase Periods, as identified in Section 3 shall be adjusted accordingly.

3. Purchasing Minimums.

3.1 Minimum Sales by Purchase Period. Subject to the terms provided herein, Raven agrees to use commercially reasonable methods to purchase the Minimum Sales Amounts of Products as set forth below:

| Purchase Period | Purchase Period Dates | Minimum Sales Amounts |

| [xxx] | [xxx] | $[xxx]USD |

| [xxx] | [xxx] | $[xxx]USD |

[xxx] Confidential information has been omitted and filed confidentially with the Securities and Exchange Commission.

3

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

Minimum Sales Amounts, as used herein, shall include the purchase price paid by Raven to AgEagle; such amounts include all amounts paid by Raven to AgEagle, all credits, and other similar amounts credited to Raven or to Raven’s account by AgEagle, as if such amounts were actually paid to AgEagle (“Sales Amount”).For the avoidance of doubt, the Minimum Sales Amount for Purchase Period [xxx], as identified in the chart above, is the cumulative amount of $[xxx]USD. Therefore, all amounts purchased from [xxx] (Purchase Period [xxx]), shall be counted towards Purchase Period [xxx], as well as the following Purchase Period of [xxx] (Purchase Period [xxx]). [xxx]. For the avoidance of doubt, [xxx].

3.2 Minimum Sales Amounts Shortfall. In the event Raven is unable to purchase the Minimum Sales Amounts as set forth herein, the Parties will work together to determine ways to increase sales. In no event shall failure to meet the Minimum Sales Amounts result in a default hereunder or termination of exclusivity. Notwithstanding the foregoing, if in any given Purchase Period the actual Sales Amounts purchased by Raven are [xxx]% or more, less than the Minimum Sales Amounts, as provided herein, then as soon as it becomes apparent to Raven the actual sales will be [xxx]% or more, less than the Minimum Sales Amounts, Raven shall inform AgEagle of such an event. Upon notification by Raven of the anticipated [xxx]% shortfall AgEagle agrees to meet with Raven, in good faith, to determine if there is a way for Raven to maintain exclusivity. If, in good faith, AgEagle is unable to reach an amicable solution with Raven and the Minimum Sales Amounts are actually [xxx]% or more, less than the above Minimum Sales Amounts, AgEagle shall have the right to terminate the exclusivity provisions of this Agreement, upon ninety (90) days’ written notice to Raven.

3.3 Condition Precedent to Minimum Sales Requirements. It is a condition precedent to Raven’s duties and obligations under this Section that the FAA rules allow for commercial use of the AgEagle System, and other similar aerial systems for the aerial collection of data in the Field, and that Raven and/or AgEagle, as applicable, is able to obtain any exemptions, certifications or licenses required thereunder, if any.

3.4 Minimum Sales Amounts Adjustment; Delay.

| 3.4.1. | FAA Approval/Certification Adjustment. If FAA, exemption, certification, or other approval is required for sale of the AgEagle System, once such certification, is obtained by Raven and/or AgEagle, as required, and AgEagle has met all requirements and/or specifications required by the FAA, if any, Raven and AgEagle will work in good faith to adjust the Minimum Sales Amounts to align with the FAA approval, requirement, and/or certification dates, if such dates had an impact on the ability to sell the AgEagle System. If the Parties are unable to come to mutually agreeable adjusted Minimum Sales Amounts, or if Raven is unable to sell the AgEagle system for the aerial collection of data in the Field, due to FAA ruling, or inability to obtain required FAA approvals, licenses, exemptions, or certifications, by October 1, 2016, Raven may, in its sole discretion, terminate this Agreement upon giving at least thirty (30) days prior written notice to AgEagle. During the thirty (30) day notice period the Parties will work together in good faith to renegotiate a new Agreement based on the landscape of potential AgEagle System approval by the FAA. |

[xxx] Confidential information has been omitted and filed confidentially with the Securities and Exchange Commission.

4

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

| 3.4.2. | AgEagle Delay Adjustment. Any delays in distribution and/or sales attributable to AgEagle or an AgEagle agent or supplier, shall result in the Purchase Periods or Minimum Sales Amounts to be adjusted accordingly. |

| 4. | Orders; Shipping; Returns. |

4.1 Purchase Orders. During the Term, Raven may purchase the AgEagle System by submitting a Purchase Order on Raven’s form (“Purchase Order”). No later than three (3) business days after receipt of a Purchase Order from Raven, AgEagle shall either accept or reject the Purchase Order, any Purchase Order not rejected within three (3) business days shall be deemed accepted. In addition to identification of the products ordered, the Purchase Order shall specify the delivery date for the products and the shipping destination and terms. After the Purchase Order is accepted, the terms and conditions set forth in the Purchase Order shall govern the purchase of the products provided therein, including, but not limited to the AgEagle System, provided that if any terms are conflicting with the terms set forth in this Agreement, the terms of this Agreement shall prevail over any conflicting terms.

4.2 Forecasts. To assist AgEagle, but without binding Raven in any manner, Raven may, in its sole discretion, also deliver forecasts or planning orders to AgEagle. All forecasts, planning orders or similar types of information provided by Raven are not and shall not be considered as binding or firm orders in any manner. All such forecasts, planning schedules or similar types of information provided by Raven to AgEagle are for planning purposes only and shall not create nor imply a firm or binding obligation of Raven to purchase any of the forecasted, planned or projected volumes provided therein.

4.3 Emergency Orders. Raven may also deliver to AgEagle emergency orders for products which require special attention as further described in Section 4.10 below.

4.4 Additional Orders. Raven may place an order which exceeds the number of products previously specified in a Purchase Order or firm orders furnished to AgEagle, and AgEagle agrees to exercise its best efforts to fill the excess portion of the order. Within ten (10) days after receipt of such an order, AgEagle will inform Raven in writing of the number of additional products it will be able to deliver to Raven.

4.5 Shipping. AgEagle shall use its best efforts to manufacture and prepare for shipment, by the delivery date specified on the Purchase Order, all accepted orders for the products to Raven, F.O.B. Origin.

4.6 Logistics. In the normal course, AgEagle shall notify Raven an order is ready to ship, and provide all applicable information for the order, three (3) days prior to shipment. Raven shall set up shipment of the same. If AgEagle must schedule a shipment for some reason, AgEagle agrees to get preapproval from Raven on the logistics for all shipments for which transportation charges are to be paid by Raven including any transportation charges that are added to the invoice as Prepaid & Add. Failure to follow this policy will result in AgEagle being responsible to pay all freight charges and any other associated penalties or fees incurred.

4.7 Returns. Raven is allowed to return up to [xxx]% of annual sales volume. Returns to be scheduled with Raven on a monthly basis and will be subject to a [xxx]% re-stocking fee. All parts will be returned in a saleable condition, and within [xxx]months of purchase from AgEagle. AgEagle will credit Raven, within forty-five (45) days of receipt, at current cost or cost paid at time of purchase (whichever is less) less the [xxx]% re-stocking fee. Freight on returns is covered by Raven.

[xxx] Confidential information has been omitted and filed confidentially with the Securities and Exchange Commission.

5

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

4.8 Failure to Meet Delivery Date. If circumstances arise that prevent AgEagle from the timely manufacture, shipment and/or delivery of the products, pursuant to an accepted Purchase Order, AgEagle shall immediately notify Raven of the nature of the problem, the methods taken to overcome the problem and the estimated period of delay. AgEagle shall have a reasonable period of time to cure such delay, which shall be determined based on the nature of the delay and needs of Raven. If it is commercially reasonable for Raven to request expedited shipment upon a delay, due to identifiable needs, AgEagle shall expedite the shipment of the product in any manner which is commercially reasonable, and shall pay all costs associated with expedited shipping for the products, above normal shipping costs.

4.9 Packaging/Marking. All products shall be properly packaged to prevent damage or deterioration and to obtain the lowest transportation rates, when paid by Raven. Raven will pay no charge for packing, drayage or storage or for preparation, crating, dunnage or other materials except as otherwise provided herein. Each packing slip, bill of lading, invoice, container, tag, and correspondence shall bear the applicable Purchase Order number and the location of the plant to which products and parts are to be shipped. A master packing slip shall accompany each shipment and shall be included in one of the packages marked “Packing Slip Inside.” All products and parts shall be properly identified as to country of origin and all documentation in connection with the products and parts shall comply with all applicable governmental regulations, and AgEagle shall indemnify Raven and hold Raven harmless from any and all costs arising out of the failure of the products to be properly marked or the failure of such documentation to comply with all applicable governmental regulations, including but not limited to:

| | 4.9.1. | All costs incurred in bringing the products and parts or the documentation into compliance with governmental regulations; |

| | 4.9.2. | All freight costs for additional materials to cover production or customer requirement; |

| | 4.9.3. | Any fines, penalties or forfeitures levied by any government or governmental agency; |

| | 4.9.4. | Any legal expenses and fees as they are incurred |

4.10 Emergency Order Fulfillment. Within 48 hours of receiving an emergency order for products outside the requirements specified in a Firm Order, AgEagle shall make the requested products ready for shipment. Immediately upon receipt of the emergency order, AgEagle shall notify the Raven Logistics Agent of the order, at which time AgEagle and the Raven Logistics Agent shall determine which Party is able to deliver the products most expeditiously and economically. If the Raven Logistics Agent requests that AgEagle ship the products, AgEagle agrees to do so and Raven shall reimburse AgEagle for the transportation costs. If the Raven Logistics Agent handles the transportation, AgEagle shall follow the instructions of the Raven Logistics Agent. If AgEagle is unable to fill the emergency order within 48 hours, AgEagle shall immediately notify Raven of the inability to fill the order and a projected time when the order can be filled. AgEagle shall keep a reasonable amount of inventory on hand to fill Emergency Orders.

6

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

| 5. | Prices and Payment. |

5.1 Prices. Subject to the adjustments as set forth herein and in Exhibit B, the prices for the AgEagle System are set forth on Exhibit A hereto, which may be updated from time to time upon mutual written agreement of the Parties. The Parties agree to meet annually to discuss any modifications to the pricing set forth in Exhibit A to account for any increase in the cost of materials, cost of regulatory changes or compliance and to remain competitive within the Field. Any price adjustments shall be mutually agreed upon between the Parties and set forth in a written document executed by authorized representatives of each Party. For the avoidance of doubt, Raven is free to set its own retail prices for the Products.

5.2 Discount. The pricing for the Products shall be subject to adjustment on a quarterly basis, based upon the volume of purchases of Products at the end of each quarter as further detailed on Exhibit B attached hereto. Any adjustments to pricing shall only be made at the end of a quarter and any adjusted pricing shall then be applicable for Products purchased in the succeeding quarter.

5.3 Most Favored Customer. AgEagle agrees to provide products and/or services to Raven on terms and conditions that are no less favorable to Raven than those of any other AgEagle customers purchasing comparable quantities of the same or similar products, regardless of territory or field of use. With respect to the products, these terms and conditions include, but are not limited to: access to comparable distribution methods and corresponding discounts, training and support services for dealers, promotional incentives, warranty procedures and administration.

5.4 Payment. All payments for products will be due to AgEagle within forty-five (45) days of the date of the invoice. A financing charge may be charged for all past due accounts.

| 6. | Term; Termination. |

6.1 Term. This Agreement shall commence on the Effective Date and shall terminate [xxx] years from the Effective Date (the “Initial Term”). Raven will have the right to renew this Agreement for an additional period of one (1) year by giving at least thirty (30) days’ prior written notice of renewal before the expiration of the Initial Term (the “Renewal Term”, and together with the Initial Term, the “Term”). If Raven gives notice of renewal, the Parties will negotiate in good faith to determine pricing and commercially reasonable minimum sales amounts or quantities to be purchased by Raven during the Renewal Term, as set forth in Section 3, in order for Raven to maintain its exclusive appointment as a distributor of the AgEagle System. If the Parties are unable to agree upon the minimum purchase quantities, then Raven shall have the right to elect to continue to be a distributor of the AgEagle System on a non-exclusive basis.

6.2 Termination. This Agreement may be terminated pursuant to the following:

| | 6.2.1. | Either party may terminate this Agreement if the other party materially breaches the Agreement, provided the non-breaching party has given the breaching party written notice of such breach and there has been a failure to cure such breach within thirty (30) calendar days after receipt of such notice. |

[xxx] Confidential information has been omitted and filed confidentially with the Securities and Exchange Commission.

7

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

| | 6.2.2. | AgEagle may terminate this Agreement if Raven fails to pay any invoice, and such default is not cured within thirty (30) days of written notice of default. |

| | 6.2.3. | Either Party may terminate this Agreement if the other Party is insolvent, unable to meet its debts as they mature, has filed a petition of voluntary bankruptcy under any chapter of the bankruptcy laws of the United States or any foreign jurisdiction; or proceedings are commenced to adjudge the other Party as bankrupt in any involuntary proceeding, the other Party makes an assignment for the benefit of creditors, a court of a receiver or trustee is appointed for the other Party or their assets or the other Party has dissolved or otherwise ceased to do business. |

| | 6.2.4. | Either Party may terminate this Agreement by giving thirty (30) days’ prior written notice of termination if either Party is unable to secure any necessary permits, licenses or other approvals from any governmental authorities, including the FAA, to the extent such permits, licenses or other approvals are required for sale of the AgEagle System. |

| | 6.2.5. | Raven pursuant to Section 3.4.1, upon giving thirty (30) days’ prior written notice of termination to AgEagle. |

6.3 Effect of Termination. Upon termination hereof, Raven shall immediately pay any amounts due to AgEagle, and AgEagle will be free to sell the AgEagle System to any person or entity or to appoint dealers or distributors to sell the AgEagle System.

6.4 Survival. The following sections (including all subsections) shall survive the termination or expiration hereof: 4 (to the extent of unpaid invoices or other amounts owed to AgEagle), 6, 7, 8, 9, 10, 11, 12 and 20.

7. Confidentiality.

7.1 Confidential Information. A Party may from time to time during the Term disclose Confidential Information (“Disclosing Party”) to the other Party (“Receiving Party”). The Receiving Party will not use any Confidential Information for any purpose not expressly permitted hereby, and will disclose the Confidential Information only to the employees of the Receiving Party who have a need to know such Confidential Information for purposes hereof and who are under a duty of confidentiality no less restrictive than the Receiving Party’s duty hereunder. The Receiving Party will protect the Disclosing Party’s Confidential Information from unauthorized use, access, or disclosure in the same manner as the Disclosing Party protects its own confidential or proprietary information of a similar nature and with no less than reasonable care. This Agreement of confidentiality shall survive the termination or expiration of this Agreement for a period of [xxx] years, and neither party may use Confidential Information received from the other party during this time to reverse engineer or otherwise recreate the other party’s proprietary Intellectual Property.

7.2 Exceptions. The Receiving Party will have no obligations under Section 7.1 with respect to any Confidential Information that:

| | 7.2.1. | Through no fault of the Receiving Party has become generally available to the public; |

[xxx] Confidential information has been omitted and filed confidentially with the Securities and Exchange Commission.

8

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

| | 7.2.2. | the Receiving Party can prove was in its possession in written form at the time of disclosure by the Disclosing Party, or was developed by the Receiving Party independently without knowledge or use of the Confidential Information; or |

| | 7.2.3. | was received by the Receiving Party from a third party who is entitled to make such disclosure and who has no confidentiality obligations owed to the Disclosing Party. |

In addition, the Receiving Party shall be allowed to disclose Confidential Information to the extent that such disclosure is (i) approved in writing by Disclosing Party, (ii) necessary for the Receiving Party to enforce its rights hereunder; or (iii) required by law or by the order of a court or similar judicial or administrative body, provided that the Receiving Party notifies the Disclosing Party of such required disclosure promptly and in writing and cooperates with Disclosing Party, at Disclosing Party’s request and expense, in any lawful action to contest or limit the scope of such required disclosure.

7.3 Return of Confidential Information. The Receiving Party will return to Disclosing Party or destroy all Confidential Information in the Receiving Party’s possession or control and permanently erase all electronic copies of such Confidential Information promptly upon the written request of Disclosing Party or the expiration or termination of the Agreement, whichever comes first. At Disclosing Party’s request, the Receiving Party will certify in writing that it has fully complied with its obligations under this Section.

7.4 Survival and Prior Agreements. Furthermore, unless mutually agreed upon by the Parties, the Parties to this Agreement agree to keep the terms of this Agreement confidential, and to refrain from discussing this information with anyone outside of the Parties. For any Confidential Information or Proprietary Information disclosed under the terms of this Agreement, the Parties shall comply with the terms hereof, as well as the terms of the Mutual Non-Disclosure Agreement, between the Parties, which is attached hereto as Exhibit C, which may be extended from time to time, and made part of this Agreement, by incorporation herein by this reference. Nothing in this Agreement shall revoke or impair the confidentiality protection provided under the Mutual Non-Disclosure Agreement for Confidential Information or Proprietary Information disclosed prior to this Agreement or outside the subject matter of this Agreement. For the avoidance of doubt, this Section 7 in no way alters or impairs the obligations of confidentiality provided under the Mutual Non-Disclosure Agreement.

8. Rights; Disclosure of Technology.

8.1 Proprietary Rights – AgEagle. All right, title and interest in and to intellectual property, owned by AgEagle as of the Effective Date (“AgEagle Pre-Existing Intellectual Property”) or conceived or developed solely by AgEagle in connection with this Agreement (“AgEagle Developed Intellectual Property”), including the AgEagle System as of the Effective Date and including, without limitation, software and electronics system design and any copyright, patent, trademark, trade secret or other intellectual or proprietary rights therein, whether registered or registerable, are the sole, confidential and exclusive property of AgEagle. Subject to Section 8.4, no right, title, or interest therein or thereto shall be acquired by Raven by virtue hereof and nothing contained in this Agreement shall be construed as granting, either expressly or by implication, estoppel or otherwise, any license under any AgEagle intellectual property now or hereafter owned or controlled by AgEagle. Notwithstanding the foregoing, for any product purchased from AgEagle under this Agreement, AgEagle hereby grants to Raven a royalty-free, worldwide, perpetual, irrevocable, and non-exclusive license under AgEagle’s rights in AgEagle intellectual property, to the extent necessary to use, sell, offer to sell, and distribute the specific purchased product only.

9

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

8.2 Proprietary Rights – Raven. All right, title and interest in and to all intellectual property, owned by Raven as of the Effective Date (“Raven Pre-Existing Intellectual Property”) or conceived or developed solely by Raven in connection with this Agreement (“Raven Developed Intellectual Property”), including products manufactured and sold by Raven (the “Raven Products”) and including, without limitation, software and electronics system design, product integration and communication of Raven Products with the AgEagle System, and any copyright, patent, trademark, trade secret or other intellectual or proprietary rights therein, whether registered or registerable, are the sole, confidential and exclusive property of Raven. Raven Intellectual Property includes, but is not limited to (a) the interaction and integration of the Raven Products with the AgEagle Products, (b) Raven technology, control systems technology, data management technology, and the interaction and integration of electrical and software libraries and components with hardware to provide integration, control functionality and data management, and (c) the design, development, testing, manufacturing, modification to make a better manufacturable product or any other product development, feature or enhancement of AgEagle System, developed in any way by Raven, whether owned, licensed, developed or first conceived prior or subsequent to the Effective Date of this Agreement. Subject to Section 8.4, no right, title, or interest therein or thereto shall be acquired by AgEagle by virtue hereof and nothing contained in this Agreement shall be construed as granting, either expressly or by implication, estoppel or otherwise, any license under any intellectual property now or hereafter owned or controlled by Raven.

8.3 Joint Intellectual Property. All right, title and interest in and to all intellectual property, conceived or developed jointly by Raven and AgEagle in connection with this Agreement shall be jointly owned by the Parties. Raven shall have exclusive rights to the Joint Intellectual Property in the Field, and AgEagle agrees not to use the Joint Intellectual Property in the Field.

8.4 [xxx] Intellectual Property Licenses.

| | 8.4.1. | Raven hereby grants to AgEagle a [xxx] license to practice all rights in Raven Developed Intellectual Property solely outside of the Field. AgEagle agrees not to use any Raven Developed Intellectual Property in the Field. |

| | 8.4.2. | AgEagle hereby grants to Raven a [xxx] license to practice all rights in AgEagle Developed Intellectual Property solely in the Field. Raven agrees not to use any AgEagle Developed Intellectual Property outside the Field. |

8.5 Limited Branding License. AgEagle hereby grants Raven the limited license to use AgEagle’s names and trademarks in connection with Raven’s efforts to sell the Products.

9. Integration. AgEagle agrees that Raven may integrate the AgEagle System and System Products with Raven Products, and any other related products, as determined by Raven, to enhance the performance capabilities of the AgEagle System or to enhance Raven’s ability to market and sell the AgEagle System. Such development and integration shall be the Proprietary Rights of Raven.

10. Warranty.

10.1 Warranty.

[xxx] Confidential information has been omitted and filed confidentially with the Securities and Exchange Commission.

10

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

| | 10.1.1. | Warranty. AgEagle warrants to Raven that (i) the AgEagle System meets Specifications, as set forth in Exhibit D, is of merchantable quality, fit for consumer sale, fit for the particular purpose for which it is sold, and is free from defects in material, design and workmanship; (ii) AgEagle shall have good title to all AgEagle Systems sold to Raven, free and clear of all liens, claims and encumbrances; (iii) the AgEagle System, and all components thereof, do not infringe on any trademark, patent right or other intellectual property right of any third party; and (iv) the AgEagle System complies with and is manufactured in accordance with applicable FAA regulations and all other applicable federal or state laws. |

| | 10.1.2. | Warranty Period. AgEagle warranties to Raven begin when the AgEagle System is delivered to Raven and continues for a period of [xxx] year from the date of retail sale to the end-user, or [xxx] years after the date of Acceptance by Raven, as defined in Section 16.3, whichever occurs first. |

| 10.1.3. | Warranty Procedure. In the event of Product failure, where it is not reasonable or feasible to repair the Product in the field, Product will be returned from Raven customers to Raven. Raven will determine if the Product is within warranty terms. If the Product is determined to be within warranty terms, AgEagle will be contacted for RMA number, and Product will be shipped to AgEagle. If after examination, AgEagle determines there is a warrantable defect due to defects in materials and workmanship, assembly and test methods, or any other by a breach of warranty, then AgEagle shall, repair or replace the Product at AgEagle’s expense or issue a credit to Raven for items that AgEagle approves for warranty. |

10.2 Cost Recovery-Rectification Work. Subject to the warranty procedure provided herein, in the event Raven confirms a warrantable defect in the Products, AgEagle will reimburse Raven for the actual cost of rectification work carried out by Raven, customers, dealers, distributors or third parties due to the warrantable defects found in the Products. Actual rectification costs shall include verifiable travel and labor costs. Raven agrees to minimize such expenses to a reasonable extent, and shall, when reasonable, use AgEagle’s support team to conduct any rectification work. If the use of AgEagle’s support team will cause delay or expense, such option is not reasonable.

11. LIMITATION OF LIABILITY. ACCEPT AS OTHERWISE PROVIDED HEREIN, IN NO EVENT SHALL EITHER PARTY BE LIABLE FOR ANY INCIDENTAL, SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF BUSINESS, LOSS OF PROFITS, LOSS OF GOODWILL, OR TORTIOUS CONDUCT RELATING TO, CAUSED BY OR ARISING OUT OF ANY BREACH OF OBLIGATIONS, SALE OF THE AGEAGLE SYSTEM, DELAY IN DELIVERY OF THE PRODUCTS, OR FROM A USER’S USE OR INABILITY TO USE THE AGEAGLE SYSTEM, EVEN IF A PARTY HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH LOSS OR DAMAGES. ANY DAMAGES THAT EITHER PARTY IS REQUIRED TO PAY FOR ANY AND ALL CAUSES, WHETHER FOR NEGLIGENCE, BREACH OF CONTRACT, OR OTHERWISE, AND REGARDLESS OF THE FORM OF THE ACTION IN THE AGGREGATE, SHALL BE LIMITED IN AMOUNT TO THE PAYMENTS MADE BY RAVEN FOR THE AGEAGLE SYSTEM SOLD TO RAVEN. THE LIMIT ABOVE SHALL NOT APPLY AND SHALL BE UNLIMITED FOR:

| | I) | MALICIOUS, WILLFULL OR WANTON CONDUCT BY AGEAGLE; |

| | II) | BREACHES OF CONFIDENTIALITY (SECTION 7); |

| | III) | WARRANTY REPAIRS, AS APPLICABLE (SECTION 10); |

[xxx] Confidential information has been omitted and filed confidentially with the Securities and Exchange Commission.

11

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

| | IV) | AGEAGLE’S OBLIGATIONS UNDER SECTION 4.9 (PACKAGING, MARKING, SHIPPING) |

| | V) | RAVEN’S RIGHTS TO RETURN REJECTED PRODUCTS UNDER SECTION 4.7 (QUALITY INSPECTION). |

12. Indemnification.

12.1 AgEagle Indemnification.AgEagle shall indemnify, defend, and hold harmless Raven from and against any losses, liability, claims, damages, penalties, costs, fees or expenses arising from or in connection with any action, proceeding or claim made or brought against Raven by any third party caused by or arising directly or indirectly from any negligence, infringement, product liability or other fault of AgEagle with respect to the AgEagle System or Product. If AgEagle is subject to indemnification under this Agreement, and such liability is the result of negligence, gross negligence or any intentional wrongdoing on the part of AgEagle, the limitations of Section 11 are not applicable to such indemnification.

12.2 Raven Indemnification.Raven shall indemnify, defend, and hold harmless AgEagle from and against any losses, liability, claims, damages, penalties, costs, fees or expenses arising from or in connection with any action, proceeding or claim made or brought against AgEagle by any third party caused by or arising directly or indirectly from any negligence, infringement, product liability or other fault of Raven with respect to Raven’s Products. If Raven is subject to indemnification under this Agreement, and such liability is the result of negligence, gross negligence or any intentional wrongdoing on the part of Raven the limitations of Section 11 are not applicable to such indemnification.

13. Marketing, Manuals, Branding.

13.1 Catalog Requirements. AgEagle agrees to accommodate the Raven parts catalogue requirements, as may be reasonably requested by Raven, and provide supporting documentation and data of part attributes including but not limited to; part description, product category, UPC, images, dimensions, weight, cross-reference data and part number to Raven for all products and components purchased hereunder.

13.2 Marketing and Marketing Support. Raven shall conduct the marketing and selling of the AgEagle System in its own name and at its own expense. Raven will use commercially reasonable efforts to promote, market and sell the AgEagle System in the Territory, which efforts may include, without limitation, presentations, technical information, meetings, discussions and demonstrations. Raven may, in its sole and absolute discretion, design Raven branded marketing materials for the AgEagle System, including, brochures, webpages and other similar marketing materials, which Raven may, when reasonable, allow AgEagle an opportunity to review. AgEagle shall support Raven’s marketing activities, as necessary, including, but not limited to, providing to Raven, at no charge, physical products (i.e. AgEagle Systems, and any other such necessary products or components) solely for use as display or demonstration units at trade fairs and events, as reasonably requested by Raven. AgEagle also agrees to make its representatives available for work in Raven booths during trade fairs as reasonably requested by Raven. Original AgEagle branded marketing materials costs, including but not limited to video presentations, brochures and advertisements shall be at AgEagle’s expense. AgEagle further agrees to provide modifiable sales documents, literature, videos, training materials etc. at no cost to Raven for use by Raven, including use by any distributors, dealers, or other third parties appointment by Raven to market or sell the AgEagle System.

12

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

13.3 Branding. Raven may, in its sole discretion, sell/re-sell the AgEagle System under any Raven, or Raven subsidiary brand. Such labeling and branding is in the sole discretion of Raven. AgEagle shall be permitted to brand the AgEagle system, in a location and size approved, in writing, by Raven, so as to complement any Raven branding. AgEagle may not in any way modify the AgEagle branding, including, but not limited to altering the color, size or placement of branding, once approved by Raven, until Raven has approved such modification in writing. AgEagle is solely responsible for the payment of all expenses and fees associated with the AgEagle branding.

14. Development, Competitiveness and Future Product Release.

14.1 Continued Development. AgEagle shall continue to develop new products and upgrades to the AgEagle System, which may include any Future AgEagle System, to maintain and improve the competitiveness of the AgEagle System and Future AgEagle Systems.

14.2 Strategic Development Planning. Additionally, the Parties agree to meet, either in person or telephonically, with such frequency as the Parties deem necessary, during the Term to identify and inform each other of new or emerging technologies, market needs, or industry trends and developments that may improve the Products covered by this Agreement or become the basis for any new products, provided that the Parties shall have no obligation to disclose information that may violate non-disclosure obligations owed to a third party or a third party’s proprietary rights.

15. Technical & Engineering Support.

15.1 Engineer Support. AgEagle will provide such engineering support and validation of the AgEagle System and the components of the AgEagle System as necessary to maintain the competiveness of the System. AgEagle further agrees to provide reasonable support, in addition to AgEagle’s other support obligations stated herein, to Raven on the Products, including, but not limited to telephone support, support at Raven’s location and field support.

15.2 Escalation Process. The Parties agree that each will establish an escalation chain between the Technical Support - Engineering entities within each company such that information needed to respond to Dealership requests for assistance that technical support experts are unable to resolve can gain assistance from expert entities within each company. Responses to inquiries from technical support experts will be expedited within each company in alignment with customer expectations for issue resolution.

15.3 Service Tooling. The Parties agree that each will have access to all special service tools that may be developed from time to time to repair components or technology covered in this Agreement. Costs associated for such required tools will be negotiated and agreed to between the Parties on an as required basis. Nothing contained herein will be deemed to obligate either Party to develop special service tools.

15.4 Product Quality Concern Meetings. The Parties agree that technical support and engineering personnel will participate, as requested, in scheduled product quality concern meetings for those products sold hereunder. Further, AgEagle will ensure its appropriate level of support and resources are offered to attend as feasibly requested by Raven. A product resolution cycle time target (in days) will be established for each concern during the initial meeting it is raised in. Target dates may be adjusted based on urgency as agreed upon by both Parties.

13

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

| | 15.4.1. | The Parties agree that all product quality concern resolutions and product evolution history will be documented and delivered in the form of an Engineering Change Order or Corrective Action Report, distributed to designated persons within each company. |

| | 15.4.2. | AgEagle will apply appropriate priority and resources to the product concern resolution meetings to meet or exceed resolution Target. When complex technical issues are encountered where root cause or resolution identification is undetermined and 75% of target resolution timeframe has elapsed, AgEagle agrees to escalate resource application or engage third party expertise dedicated to developing a resolution for that issue. |

| | 15.4.3. | AgEagle agrees to share full clarity, in the event of a product failure, all test results and findings of its own investigation of failure resolution (Manufacturing Data, Test Results, and Data Analysis). |

| | 15.4.4. | In all cases, Parties agree to work together to expedite resolution to identified product concern. |

15.5 Engineering Documentation. Prior to distribution of the AgEagle System, AgEagle must supply to Raven, at a minimum, the following engineering documentation and design information that AgEagle has, can obtain from a third party, or can create from information on hand or obtained from a third party:

| 15.5.1 | Durability test results (Temperature/Vibration/Humidity/Electronic/Electrostatic Discharge). |

| | 15.5.2 | Potential Design Improvements. |

| | 15.5.3 | Production failure types and rates. |

| | 15.5.4 | Repair Failure types and rates. |

| | 15.5.5 | Supplier Quality Audit (ISO9001 or similar standard as approved by Raven). |

| | 15.5.6 | Regulatory Compliance (CE, FCC, International Certifications, and any other reasonably requested, or otherwise required regulatory compliance documentation). Any certifications required to sell the Product will be paid for by AgEagle, unless the Parties agree otherwise. |

| | 15.5.7 | All required FAA certifications and exemptions. |

| | 15.5.8 | A detailed plan for training on field support and deployment of Product and training on design details and detailed technical information to support integration efforts. |

| | 15.5.9 | Full understanding and drawings of the different kits that are going to be sold. |

| | 15.5.10 | Full understanding and drawings for the repair parts for the different kits. |

| | 15.5.11 | Full Engineering Specification of the AgEagle Rapid Wing including tested results. |

14

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

If AgEagle does not have access to any of the above information, the Parties will work together to locate appropriate alternative information, or begin creating such information/data going forward. Access as used herein includes the ability to request information through a third party (i.e. supplier). To the extent certain testing or information is required from a Supplier, AgEagle will pay any necessary fees to get such information, if it is necessary for the proper sale and testing of the Product.

15.6 Training. Raven shall be responsible for providing all training and support to any applicable dealers/distributors and end-users in Raven’s distribution network. AgEagle agrees to train Raven personnel in the use of the AgEagle System and to provide Raven with such other technical support as may be necessary for Raven to provide support to the end users of the AgEagle System. Specifically, AgEagle shall provide, at a minimum the following training:

| | 15.6.1. | AgEagle agrees to provide Raven corporate at no charge the same training that it usually provides to its own dealers/distributors for the Term of this Agreement. Training will be provided to Raven in a train the trainer type of approach; Raven will be responsible for dealer training and end user training. AgEagle will also provide at no charge reasonably requested support directly to Raven corporate. This may include, but is not limited to, phone support, escalation support and in-person field support. |

| | 15.6.2. | AgEagle agrees to provide reasonable sales, engineering, system engineering, training and product support to Raven team members and in the following Raven and/or Raven affiliate locations upon Raven’s request, worldwide. The support and training provided by AgEagle will consist of the following: |

| | 15.6.3. | Factory Training. |

| | a. | In person installation and troubleshooting training at Raven factories at Sioux Falls, SD, and locations as required. |

| | b. | Training provided at the initial launch of the product from the facilities, to be coordinated with Raven. |

| | 15.6.4. | Technical Support. |

| | a. | Technical training provided in each region within 3 months of introduction in each region. Technical training is for service and maintenance of the product. |

| | b. | All training dates and locations to be coordinated with Raven regional and global marketing teams. |

| | i. | In person technical training by AgEagle is to be provided for Raven employees (Technical support, MFSO, RMSO, etc.). Raven is responsible for providing training for dealers on an ongoing basis, as necessary. |

| | ii. | Ongoing product support is to be provided to the technical support team, via phone, or in person if issues cannot be resolved over the phone. Technical support shall be provided by an engineer or other person of equivalent knowledge to handle the issue and reach resolution. |

15

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

| | c. | Operations Manual. AgEagle will assist with the creation of an operations manual, by providing content, art and troubleshooting data to create the Raven operation manuals. |

| | d. | Commercial Training. AgEagle will provide in person product training to Raven personnel in each region within 3 months of introduction, or other time as mutually agreed on between the Parties. Commercial training includes, but is not limited to product use, operation, and product benefits |

Failure to timely provide the information or training provided for herein is a breach hereof, pursuant to this Section. If AgEagle’s failure to timely file such training or information delays the distribution of the AgEagle Systems, then minimum quantity periods pursuant to Section 3 shall be adjusted accordingly.

16. Specifications, Standards of Quality; Acceptance.

16.1 Specifications. All of the Products shall conform strictly to the Specifications attached hereto as Exhibit D, and any other specifications agreed in writing by Raven and AgEagle (collectively “Specifications”) and shall be in accordance with designs, drawing, samples and standards of quality and workmanship approved by or on behalf of Raven, as applicable.

16.2 Quality Standards. AgEagle must meet all of the criteria set forth in Raven’s Supplier Quality Requirements Manual (“SQRM”), attached hereto as Exhibit E, as amended from time to time, and any applicable ISO quality standards. AgEagle agrees that Raven may, during regular business hours and upon three (3) business days’ notice to AgEagle, inspect AgEagle’s manufacturing processes and facilities to ensure AgEagle’s continued compliance with the SQRM and applicable ISO standards. At any time that Raven determines that the Products or AgEagle’s processes do not meet Raven’s SQRM, Raven may initiate a stop shipment procedure and any deficiencies in Products must be corrected by AgEagle, at its expense, prior to any subsequent Product shipments.

16.3 Product Inspection and Acceptance. Raven shall not be deemed to have accepted any product until such product has been received by Raven’s manufacturing or other designated facility to which such products are delivered and Raven has had reasonable time to inspect the products. In no event shall such time for acceptance be less than ten (10) days from the date of delivery by AgEagle. All products are deemed accepted unless rejected in writing within fourteen (14) days from the date of delivery by AgEagle. Neither Raven’s inspection of, or failure to inspect, the products, acceptance of the products, or payment for, or use of the products shall relieve AgEagle of any of its obligations under this Agreement.

16.4 Rejection of Nonconforming Products. If any products delivered to Raven do not conform to the provisions of this Agreement or other commercially reasonable standards, Raven shall have the right, at its discretion, to (a) obtain from AgEagle, free of charge, the replacement of such products and shall promptly return any rejected product to AgEagle, (b) reject such products, without replacing them, and require AgEagle to repay the price of such rejected products in full, or (c) repair such products, at AgEagle’s risk and cost.

16.5 Corrective Actions by AgEagle. Upon notice from Raven of a nonconforming or defective product, AgEagle shall (a) promptly inform Raven of the likely causes for such nonconformance or defect, and of the corrective actions identified to remedy such nonconformity and/or defect in compliance with Raven’s quality standards, and shall identify the particular products affected (by serial number or other means), (b) without delay, but subject to advance written approval of Raven, introduce into its own manufacturing processes appropriate remedial actions, in accordance with any reasonable instructions Raven may issue; and (c) implement, in accordance with Raven, a control plan to verify and confirm the effectiveness of such remedial actions.

16

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

17. Availability of Products.

17.1 Inventory on Hand. Raven and AgEagle agree that AgEagle shall hold approximately two (2) weeks of finished goods inventory for high volume products at AgEagle’s facility. The amount of finished goods inventory shall be determined based on the actual shipments made in the prior two weeks by AgEagle to Raven. AgEagle shall provide Raven with an electronic version of a current inventory list by high volume finished goods product on a monthly basis to aid in maintaining these inventory levels. In the event demand is added within the inventory window agreed upon between Raven and AgEagle, AgEagle shall assess and communicate its ability to support such additional inventory demands. Raven and AgEagle shall revisit the minimum and maximum inventory levels as needed to ensure market conditions are effectively supported.

17.2 Capacity.Should AgEagle become unable to provide adequate quantities of products or parts to satisfy total industry demands, AgEagle shall use commercially reasonable efforts to increase the available supply of products to Raven on a nondiscriminatory basis with other suppliers, such that the supply of products and parts to Raven will be fifty percent (50%) greater than Raven’s estimated annual requirements based on the most recent forecast. For clarity, AgEagle shall use commercially reasonable efforts to flex supply to Raven at 50% over forecast without adding lead time.

17.3 Discontinued Product Availability. AgEagle agrees to make discontinued Products, or an equivalent thereof, available for sale to Raven for a period of five (5) years from the date of discontinuance unless AgEagle is producing a substituted item that can replace the discontinued version. The price for discontinued Products, Products substitutes, and Products supplied to Raven by AgEagle after expiration or termination of this Agreement shall not exceed the lowest price then offered by Raven to a third party or, if none exists, then the price shall be the fair market value as agreed upon by AgEagle and Raven. The price of a discontinued Product shall not increase by more than two percent (2%) per year, from the time that such Product was discontinued, unless the annual volume sold of the discontinued item drops by 70% or more from the prior year.

17.4 Supply of Parts. AgEagle agrees to supply Service Parts to Raven for a period of five (5) years from the date this Agreement expires or is terminated, or for a period of five (5) years after any product exits the market, whichever comes earlier.

18. Compliance.

18.1 NAFTA. Upon request and where applicable, AgEagle shall promptly furnish Raven an accurate and complete Country of Origin or Manufacturer’s Affidavit in accordance with applicable laws and regulations. AgEagle agrees to indemnify Raven and/or its customers against all loss resulting directly or indirectly from AgEagle’s delay in furnishing such certificates to Raven and from incorrect information therein furnished by AgEagle.

18.2 Conflict Minerals. AgEagle shall, within a reasonable period of time, following each calendar year in which it has delivered any goods to Raven, under this Agreement or otherwise, complete and provide to Raven a single and comprehensive Conflict Minerals Reporting Template, using the form provided by Raven, and attached hereto as Exhibit F. AgEagle shall perform appropriate due diligence on its supply chain in order to fulfill the reporting obligations of this Section.

17

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

18.3 EAR/ITAR Classification. AgEagle certifies that any of the Products hereunder that are classified on the Commerce Control List (15 C.F.R. Part 774, Supplement No. 1) and/or the International Traffic in Arms Regulations (ITAR) (22 C.F.R. Chapter I, Subchapter M, Parts 120-130) have the classifications as set forth in Exhibit G, including, but not limited to all applicable Harmonized Tariff Codes, ECCN’s or ITAR categories.

18.4 Harmonized System Codes. AgEagle agrees to provide Raven with the applicable Harmonized System code for the Products as designated by the Harmonized Tariff Schedule of the United States for Products imported into the United States, or the ten (10) digit Schedule B number administered by the U.S. Commerce Department, Census Bureau, Foreign Trade Division for Products exported from the United States.

18.5 Ingredients Disclosure, Warnings. AgEagle shall promptly furnish to Raven in such form and detail as Raven may direct:

| | 18.5.1. | A list of all hazardous ingredients in the Products. |

| | 18.5.2. | The amount of each of such ingredient. |

| | 18.5.3. | Information concerning any changes in or additions to such ingredients. |

Prior to and with the shipment of the Products, AgEagle agrees to furnish to Raven sufficient warning and notice in writing (including appropriate labels on Products, containers and packing) of any hazardous material which is an ingredient or a part of any of the Products, together with such special handling instructions as may be necessary to advise carriers, Raven, and their respective employees how to exercise that measure of care and precaution which will prevent bodily injury or property damage in the handling, transportation, processing, use, or disposal of the Products, containers and packing shipped to Raven. AgEagle agrees to comply with Raven Industries Applied Technology Division’s Restricted Materials list, as may be updated from time to time, which is attached hereto as Exhibit H.

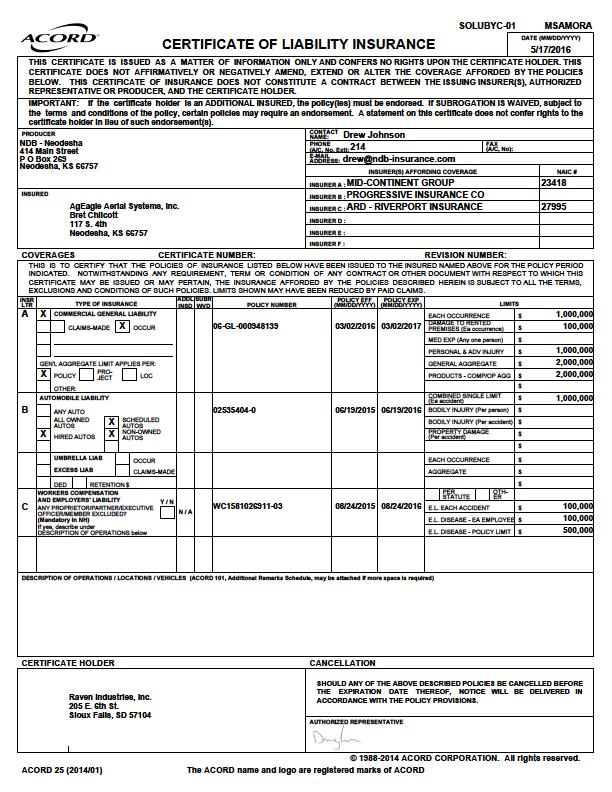

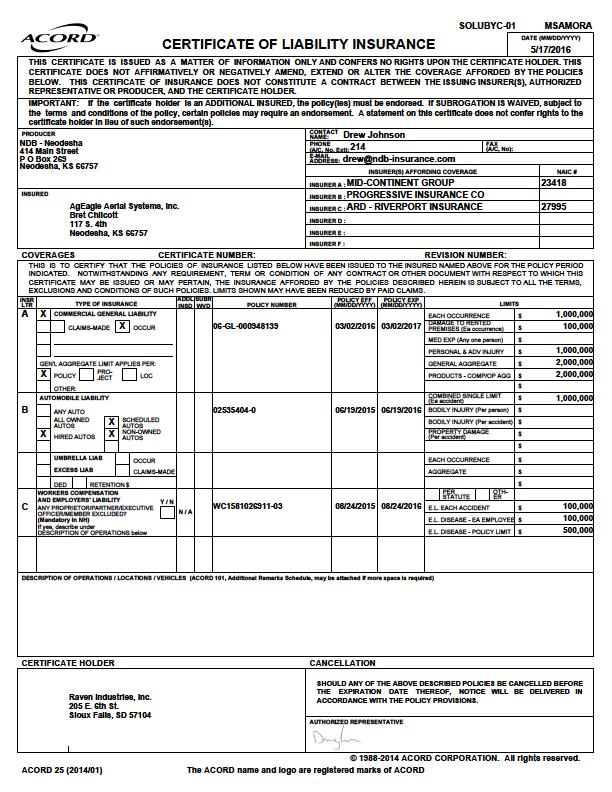

19. Insurance. AgEagle agrees to maintain during the Term of this Agreement, commercial general liability insurance, including, products liability and completed operations coverage, blanket contractual liability and broad form property damage, with limits of at least $1,000,000 for each occurrence, with Raven specifically included as an additional insured in any such policy. AgEagle will provide, on the Effective Date, as Exhibit I, and thereafter upon the reasonable request of Raven, with a copy of certificate of insurance identifying Raven as an additional insured thereunder.The policy shall contain a “severability of interest” clause and will provide that AgEagle’s coverage shall be primary to any other insurance available to or maintained by Raven.All certificates of insurance shall include a clause obligating the insurer to give Raven not less than thirty (30) days prior written notice of any material change in, cancellation of, or intent not to renew the insurance.

20. Miscellaneous.

20.1 Assignment. Neither Party may assign this Agreement or its rights, or delegate its duties or obligations hereunder without the other Party’s prior written consent. Any such assignment, delegation or other transfer in contravention of this provision shall be null and void. This Agreement shall inure to the benefit of and be binding on the respective successors and permitted assigns, if any, of the parties hereto.

18

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

20.2 Section Headings. The Section headings throughout the Agreement are for reference purposes only, and the words contained therein shall in no way be held to explain, modify, amplify or aid in the interpretation, construction or meaning of the provisions hereof.

20.3 No Third Party. Except as otherwise specifically stated herein, the provisions hereof are for the benefit of the Parties hereto and not for any other person.

20.4 Non-waiver. Any failure or delay by either Party to exercise or partially exercise any right, power or privilege hereunder shall not be deemed a waiver of any of the rights, powers or privileges under the Agreement. The waiver by either Party of a breach of any term, condition or provision hereof shall not operate as, or be construed as, a waiver of any subsequent breach thereof.

20.5 Modifications, Amendments or Waivers. No modifications or amendments to the Agreement and no waiver of any provisions hereof shall be valid unless made in writing signed by duly authorized representatives of the Parties.

20.6 Governing Law. This Agreement shall be governed by and construed in accordance with the laws of the New York. The federal and state courts in New York shall be the exclusive forum for any action brought hereunder, and both Parties consent to the jurisdiction of the state and federal courts in the State of New York.

20.7 Severability. If any term, provision or part hereof is to any extent held invalid, void or unenforceable by a court of competent jurisdiction, the remainder hereof shall not be impaired or affected thereby, and each term, provision, and part shall continue in full force and effect, and shall be interpreted in a manner consistent with the intent of the Parties.

20.8 Relationship of Parties. Both Parties hereto, in the performance hereof, will be acting in separate capacities and not as employees, partners or joint ventures, of one another. With regard to the performance hereof, each Party acknowledges that it does not have the authority to act for or in the name of the other Party or to commit the other Party in any manner whatsoever. The employees of one Party shall not be deemed or construed to be the employees of the other Party for any purpose whatsoever.

20.9 Force Majeure. Neither Raven nor AgEagle shall be in default or liable for any delay in or failure of its performance due to causes beyond its reasonable control, including, but not limited to, acts of god, natural catastrophes, governmental acts or omissions, labor strikes, lockouts or other disturbances, war, riot, boycotts, embargoes, terrorist or criminal acts or extraordinary difficulties in procuring labor or indemnification materials, computer viruses, equipment or transmission failure or damage.

20.10 Notices. All notices to be given under this Agreement shall be deemed given as of the date of receipt via personal delivery, courier service, or Certified U.S. Mail, Return Receipt Requested. Notices shall be given using the following contact information, which may be amended from time to time by written notice to the other Party.

19

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

| If to Raven: Raven Industries, Inc. 205 E 6th Street Sioux Falls, South Dakota 57104 Attention: General Manager & Vice President of ATD E-mail: With copy to: Raven Industries, Inc. 205 E 6th Street Sioux Falls, South Dakota 57104 Attention: Legal Counsel E-mail: | If to AgEagle: AgEagle Aerial Systems, Inc. 117 S. 4th Street Neodesha, KS 66757 Attention: Mr. Bret Chilcott E-mail: |

20.11 Entire Agreement. The Agreement and the Exhibits attached hereto, constitute the entire agreement, understanding and representations, expressed or implied, between Raven and AgEagle with respect to subject matters described herein, and supersede all prior written and oral communications, agreements, letters of intent, representations, warranties, statements, negotiations, understandings and proposals, with respect to such subject matters.

20.12 Compliance with Laws. Both Parties agree to comply with all applicable laws and regulations, including, without limitation, the requirements of the U.S. Foreign Corrupt Practices Act (“FCPA”), as amended from time to time, the U.S. economic sanctions regulations administered by the U.S. Treasury Department’s Office of Foreign Assets Control (“OFAC”), as amended from time to time, the OECD “Convention on Combating Bribery of Foreign Public Officials in International Business Transactions”, and the “United Nations Convention against Corruption.” Each Party agrees to comply with the other Party’s reasonable policies designed to ensure compliance with applicable laws and regulations, including, for example, through annual certifications of compliance with applicable laws.

20.13 Export Compliance. Each Party acknowledges that the laws and regulations of the United States restrict the export and re-export of commodities, certain products and technical data of United States origin. Each party agrees that it will not export or re-export restricted commodities or the technical data of the other party in any form without the appropriate United States and foreign government licenses.

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

| RAVEN INDUSTRIES, INC. | AGEAGLE AERIAL SYSTEMS, INC. | |||

| By: | /s/ Brian Meyer | By: | /s/ Bret Chilcott | |

| Name: | Brian Meyer | Name: | Bret Chilcott | |

| Its: | Vice President of ATD | Its: | CEO | |

20

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

Exhibit A – Pricing

Exhibit B – Pricing Adjustments

Exhibit C – NDA

Exhibit D – Specifications –

Exhibit E – Supplier Quality-Manual

Exhibit F – Conflict Minerals

Exhibit G – ECCN/ITAR/EAR info

Exhibit H – Restricted Materials List

Exhibit I – Insurance

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

EXHIBIT A

PRICING

AGEAGLE SYSTEM

| Item Description | Item # | Raven NET Price |

| AgEagle RAPID Plus wing with navigation system and camera (does not include RAPID subscription) | AGERBLG | TBD |

| Launcher | AGELAS | TBD |

| Ground support equipment | AGEGSP | TBD |

| RAPID subscription* | RPDSUB | See Table Below |

| TOTAL AGEAGLE RAVEN NET SYSTEM PURCHASE PRICE | $[xxx] |

The subscriptions below are a pass through charge with no discount:

| Off line processing subscription | On line processing subscription |

| Does not require cellular data plan nor does it require cellular data to fly or capture images | Includes all features of the “Off Line” plus the ability to use cellular connectivity to automatically upload images from the aircraft when in cellular range |

| Geo referenced images are created automatically | Rapid preview images on tablet device moments after flight |

| No Cellular data required | Images are automatically uploaded so no need to upload at the office |

| Images are uploaded via WiFi at office or home | |

| Flight planning from tablet | |

| Images are stored on a cloud server for easy access | |

| Untimed acres | |

| $1,500 per year* | $3,000 per year* |

*AgEagle and Raven will use their best efforts to determine if there is a way to reduce the cost of all the items provided herein, in a way that is advantageous for AgEagle and Raven. If AgEagle and Raven determine a way to reduce these costs, the Parties will work together to agree on new pricing that reflects the cost reductions that are beneficial to both AgEagle and Raven, and such price reductions shall be taken into account in Section 3, upon the date such new pricing becomes effective.

[xxx] Confidential information has been omitted and filed confidentially with the Securities and Exchange Commission.

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

EXHIBIT B

PRICING ADJUSTMENTS

This Exhibit was not provided at the time of the execution of the Agreement.

[CERTAIN PORTIONS OF THIS EXHIBIT HAVE BEEN OMITTED BASED UPON A REQUEST FOR CONFIDENTIAL TREATMENT. AN UNREDACTED VERSION OF THIS DOCUMENT HAS ALSO BEEN PROVIDED TO THE SECURITIES AND EXCHANGE COMMISSION.]

EXHIBIT C

NON-DISCLOSURE AGREEMENT

This Agreement ("Agreement") is entered into and effective as of October, 12, 2015, between AgEagle Aerial Systems "Company"), and Raven Industries, Inc. "Client"). The parties hereby agree as follows:

l. Purpose. The parties wish to explore a business opportunity including a possible investment, merger, acquisition or services agreement between them, and in connection with this opportunity, Company may disclose to the Client and Client may disclose to the Company certain confidential technical, legal, marketing and business information which the disclosing party desires to treat as confidential.

2. "Confidential Information" means any information disclosed by one party (or its agents or affiliates) to the other, either directly or indirectly, in writing, orally or by inspection of tangible objects including without limitation documents, computer programs, software, prototypes, samples, designs, drawings, databases, schematics, formulas, inventions and know-how, trade lists or plans, business plans, product development plans and schedules, financial materials, strategic information, forms of agreements, and information relating to customers, suppliers, personnel and consultants. Confidential Information shall also include (a) any information, material or data provided by third party vendors of the disclosing party; and (b) any analysis, compilations, studies, summaries, extracts or other documentation prepared by the receiving party based on the Confidential Information disclosed by the disclosing party or its vendors. Information communicated orally shall be considered Confidential Information if such information is confirmed in writing as being Confidential Information within thirty (30) days after the initial disclosure.